Rolling in the fast lane

Trenchless International April 2015

ProKASRO has recently launched the UV-CCU, a new highly mobile UV system for sewer rehabilitations.

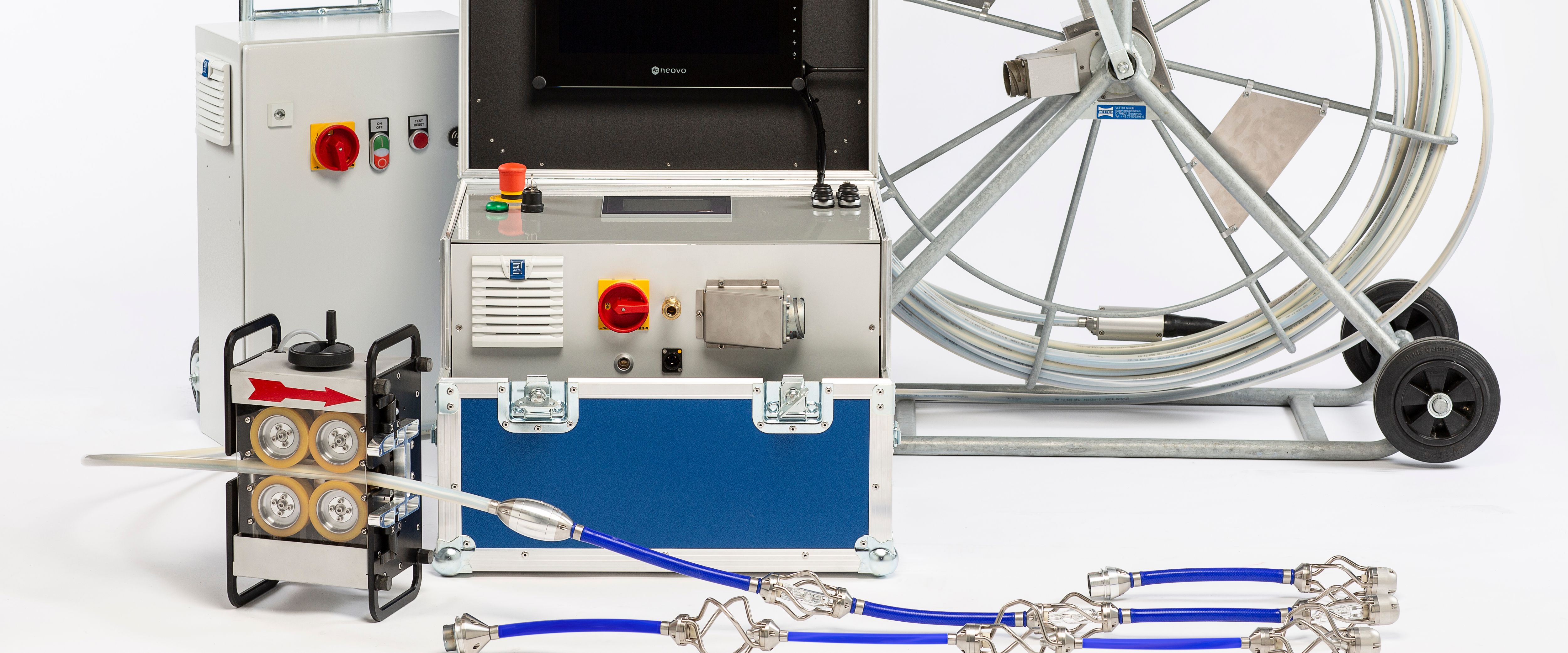

Combining a UV control unit and a 200 m cable drum into a compact system, the UV-CCU intends to make sewer rehabilitation easy to execute, even within very narrow confines. Since the system’s launch in January 2015, ProKASRO has received a significant level of interest from both existing and potential clients, with ten units sold since product launch.

Combining a UV control unit and a 200 m cable drum into a compact system, the UV-CCU intends to make sewer rehabilitation easy to execute, even within very narrow confines. Since the system’s launch in January 2015, ProKASRO has received a significant level of interest from both existing and potential clients, with ten units sold since product launch.

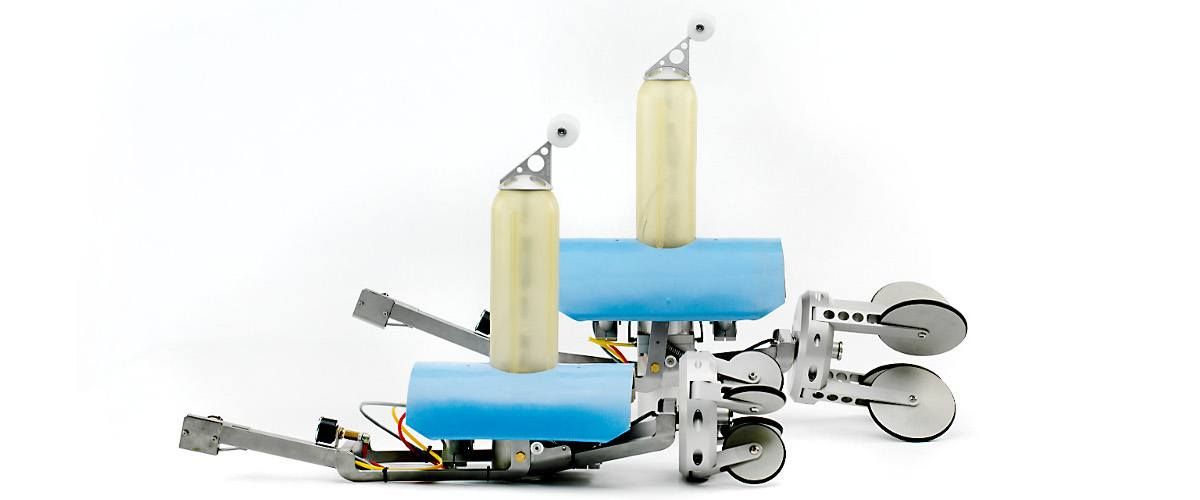

The system is ideal for any business or contractor that can see and understand the benefits of having all functions and operations controlled from a single unit. With a maximum cable length of 200 m, the system can control a standard KASRO UV light source of 8 x 400/600 W for pipes ranging from 150-500 mm in diameter. For larger pipes ranging from 550-1200 mm in diameter, the system can also accommodate a KASRO UV light core of 8 x 1000 W.

Consistent cures

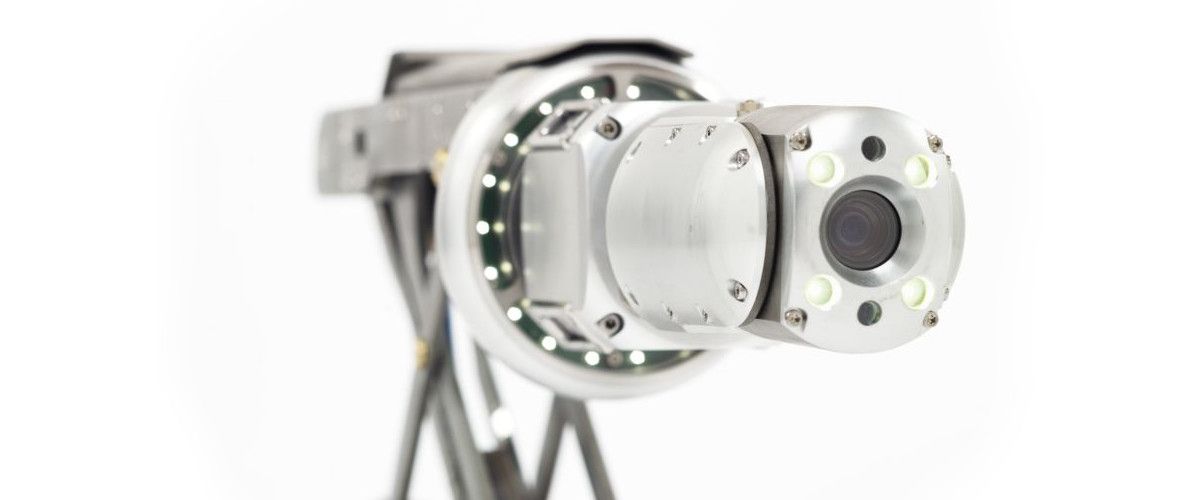

To ensure the UV light source is pulled back at a constant speed, thereby allowing the liner to be cured consistently, the complete curing operation of the cured-in-place pipe liner is controlled via the system’s installed laptop located above the electric-driven cable drum. The on-screen display, visualisations and protocol data logging are also located there.

To ensure the UV light source is pulled back at a constant speed, thereby allowing the liner to be cured consistently, the complete curing operation of the cured-in-place pipe liner is controlled via the system’s installed laptop located above the electric-driven cable drum. The on-screen display, visualisations and protocol data logging are also located there.

A complete UV rehabilitation system in one unit with a minimum space outlay, the UV-CCU can be deployed from a work van, with the unit able to be deployed via lifting platform to job sites such as footpaths, cycle paths or alongside a railway line. According to ProKASRO, the system’s portability even allows UV curing work to occur in garages or halls, with the system able to be transported in an elevator or carried through doorways.

A complete UV rehabilitation system in one unit with a minimum space outlay, the UV-CCU can be deployed from a work van, with the unit able to be deployed via lifting platform to job sites such as footpaths, cycle paths or alongside a railway line. According to ProKASRO, the system’s portability even allows UV curing work to occur in garages or halls, with the system able to be transported in an elevator or carried through doorways.

“With the UV-CCU weighing approximately 530 kg and mounted on four wheels, small job-sites become possible, such as installing a liner measuring only 15 m. It can be moved by only one person”, said a company spokesperson.

New developments

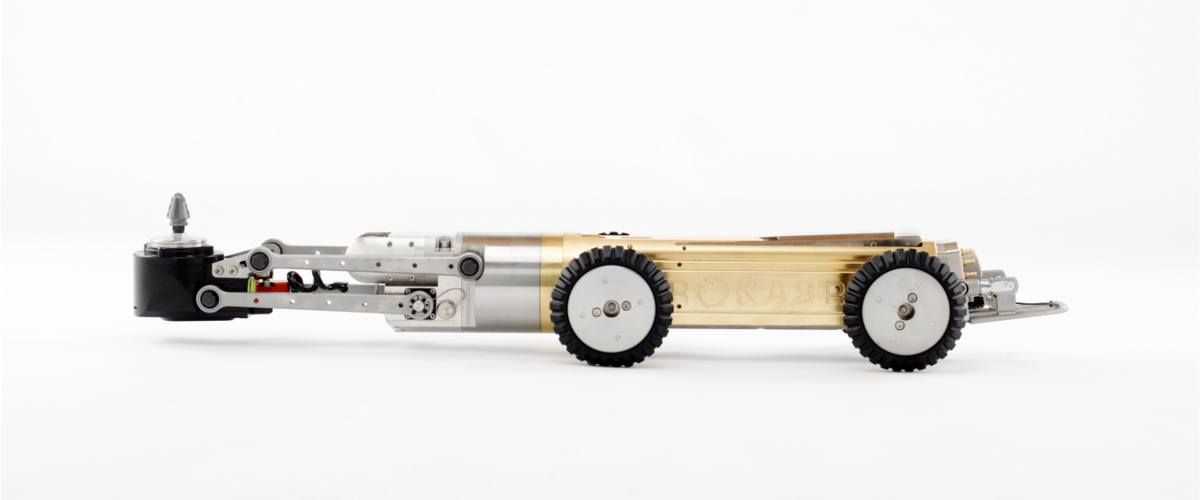

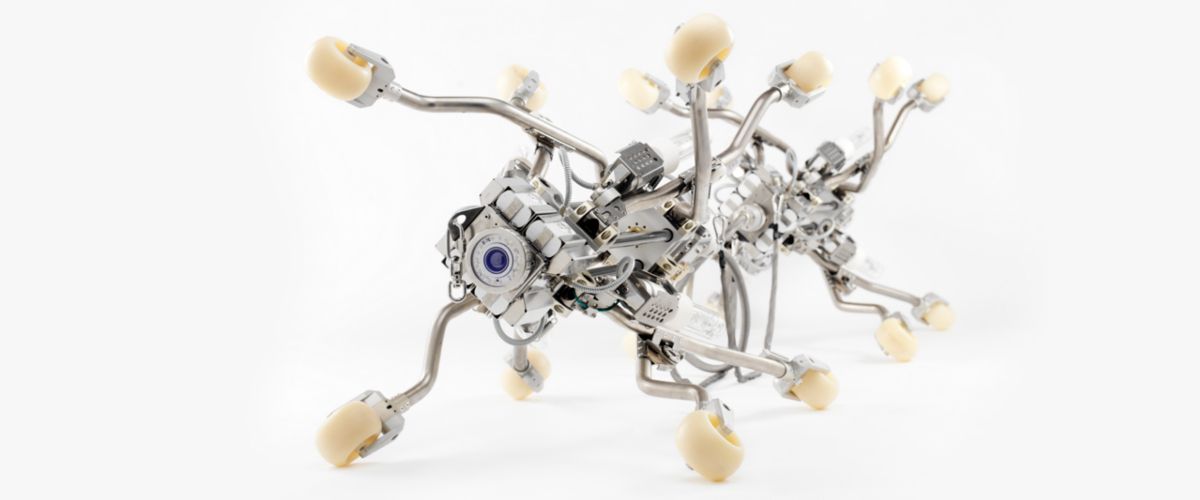

For CIPP diameters up to 1200 mm, the UV light core has been electrically adjusted for added stability and decreased weight, continued the spokesperson ProKASRO.

“The lamps are distributed symmetrical around the core and are placed closer to the laminate,” commented the company. “Through that, the light curing of the liner gets more efficient as well as more consistent – a higher lamp performance is not necessary to ensure a high-quality polymerization during the curing process. The nearer the lamps get to the laminate, the faster it is being cured with a small energy consumption.”

For over a decade ProKASRO has designed, developed and manufactured more than 250 UV systems and distributed them worldwide, with all development processes conducted in-house. Whether completely mobile or built into a vehicle or a container, ProKASRO can accommodate any customer preferences and meet all construction requirements.

The UV CCU as well as the new KASRO UV light core are being launched officially at RO-KA-TECH 2015 from 6-8 May. To see the products up close visit stand #A06 in Hall 3.