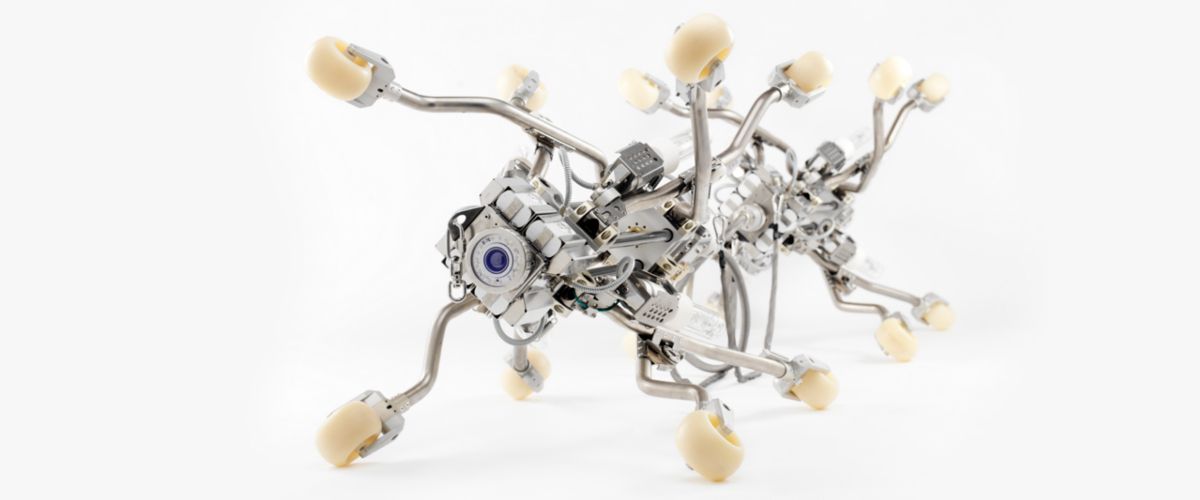

Electric driven KASRO working robot is on the advance

Trenchless International April 2014

The very first electric powered vehicle was introduced to the streets of Paris in the year 1881. The Frenchman Gustave Trouvé developed the first electric powered vehicle and could drive at 12 km/h and had a range of 14 to 26 km. Five years later the electric powered technology was displaced by the invention of the internal combustion engine / v-engine by the German engineer Carl Benz.

Over a century later the electric motor is experiencing a comeback due to an increasing environmental awareness and the shortage of natural reserves and resources.

The different modes of driving also play a significant role in regards to milling robots within sewer rehabilitation. They are a factor in deciding the efficiency of the rehabilitation, environmental sustainability and both employee and public safety at the work site.

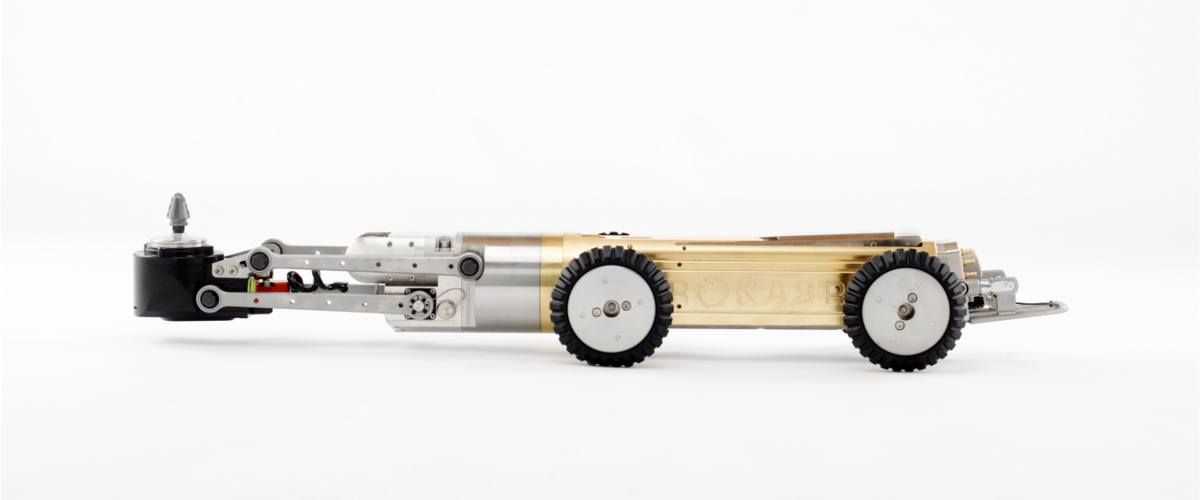

ProKASRO expanded its product portfolio with electric driven milling robot systems in 2012. A wise investment in the future which strikes a significant resonance on the market. The increase in electric robot systems started up especially on the American market. The distributor in America Aries Industries Inc., experienced the Pumper & Cleaner Show as very successful and faced another boost in selling electric robot systems. Within a short period of time 20 electric driven robot systems have been put into operation worldwide.

The benefits speak for themselves:

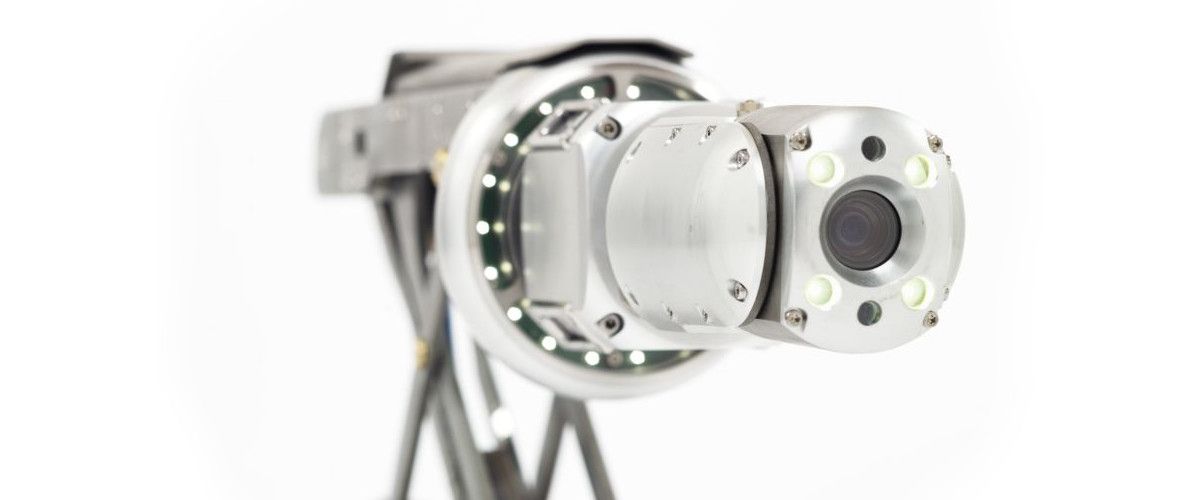

The high performance of the KASRO electric motor of up to 3000W enables the highest efficiency during milling works and reduces the rehabilitation time on-site. At the same time the power supply is guaranteed via battery packs with inverter for up to 14 hours continuous use meaning a separate electric generator is not necessary. Therefore we can speak about the most economically advantageous form of a rehabilitation vehicle for working robots.

The high performance of the KASRO electric motor of up to 3000W enables the highest efficiency during milling works and reduces the rehabilitation time on-site. At the same time the power supply is guaranteed via battery packs with inverter for up to 14 hours continuous use meaning a separate electric generator is not necessary. Therefore we can speak about the most economically advantageous form of a rehabilitation vehicle for working robots.

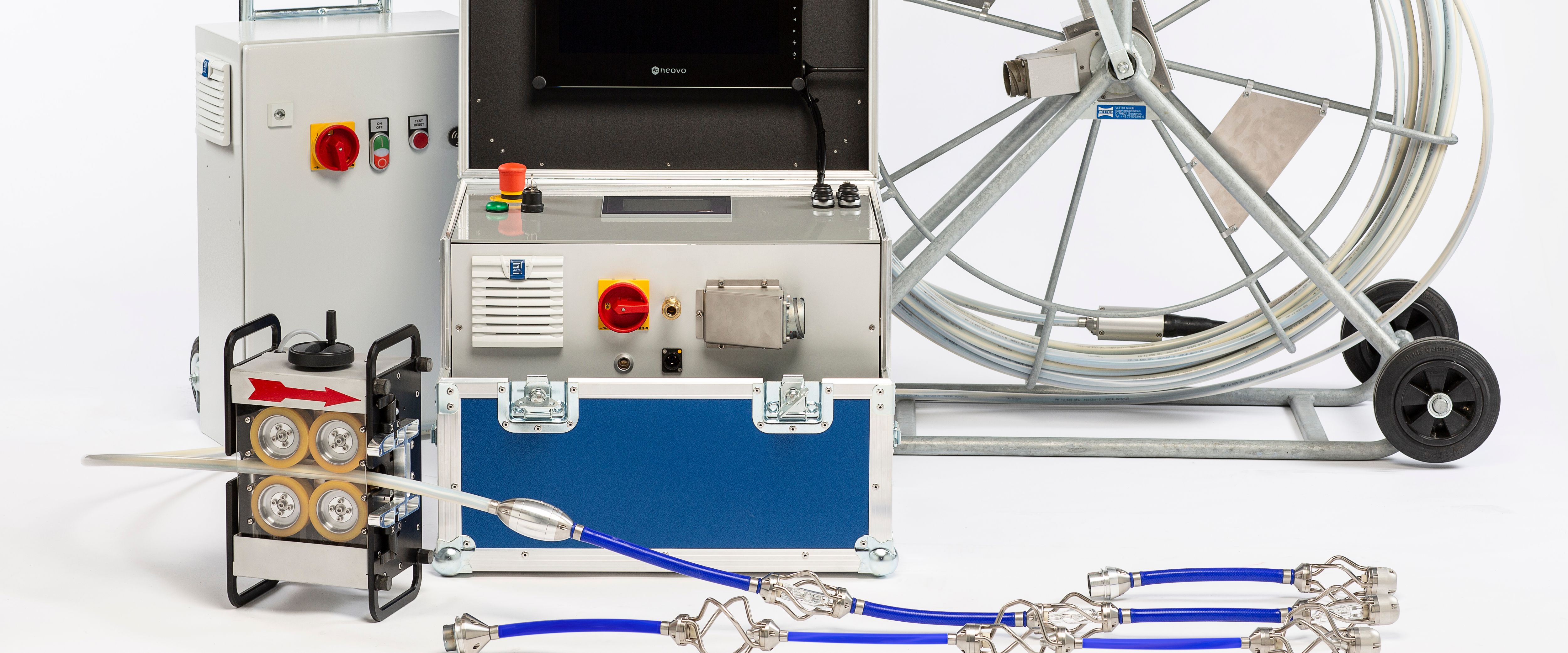

Another advantage is the space saving in regards to the rehabilitation vehicle – for now it is possible to place all the equipment of a complete KASRO electric milling robot system within a 3.5t vehicle. So the vehicle can be driven by a normal driver´s license. Therefore, a driver´s license for heavy good vehicles (trucks) is no longer required. Even tight streets can be negotiated with the 3.5t vehicle and the rehabilitation procedure can be operated in an efficient manner even in hard-to-reach areas.

The electric milling robot also creates a comfortable working atmosphere. The noise level is minimal which is ideal for the neighborhood of the construction site. Milling works can be operated anytime without disturbing the general public.

Finally the aspect of environmental sustainability should be highlighted. The electric drive keeps the fuel consumption, CO2-emissions and pollution to a minimum.

The new electric KASRO working robot within a 3.5t vehicle was first introduced during the RO-KA-TECH exhibition held in Kassel, Germany in March 2013. As a result of this, ProKASRO faces a boom in demand for this type of rehabilitation equipment. All tests and construction sites were operated to a maximum satisfaction. During liner preparation or opening lateral connections; the works on-site can take place the whole day without the vehicle losing its battery power.

Has your level of interest raised or do you have a KASRO pneumatic robot system?

No problem! As ProKASRO solutions for sewer rehabilitation look to improve both sustainable and long-term benefits, we now offer a conversion of your existing system as an alternative to a new acquisition.

What is contained in the Converter-Kit for the Electro-Robot?

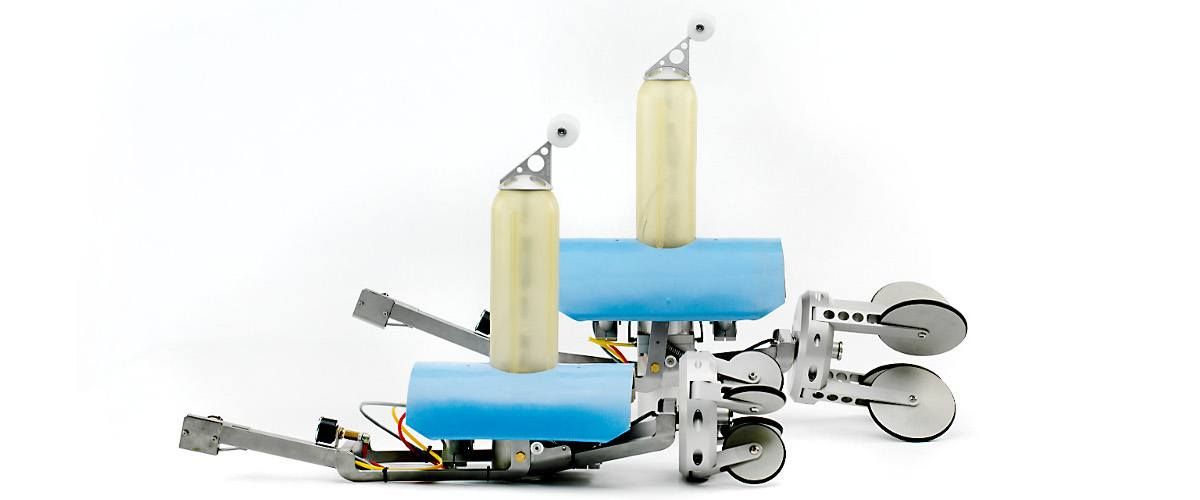

The pneumatic driven KASRO milling motor will be substituted with an electric driven KASRO milling motor. Within the cable drum an electro cable will be passed through the air hose and the rotary feed will be upgraded. The control unit will get a software update for the electro robot. Also a new combination cable coupling with plug for the electric motor is added. Finally you have the option to remove the compressor and to replace the generator with the long life battery pack.

So feel free to contact us at