Sewer solutions made in Germany

Trenchless International Januar 2015

Efficient sewer system are an essential part of the urban infrastructure, therefore having a continuous program of sewer rehabilitation is of equally high importance.

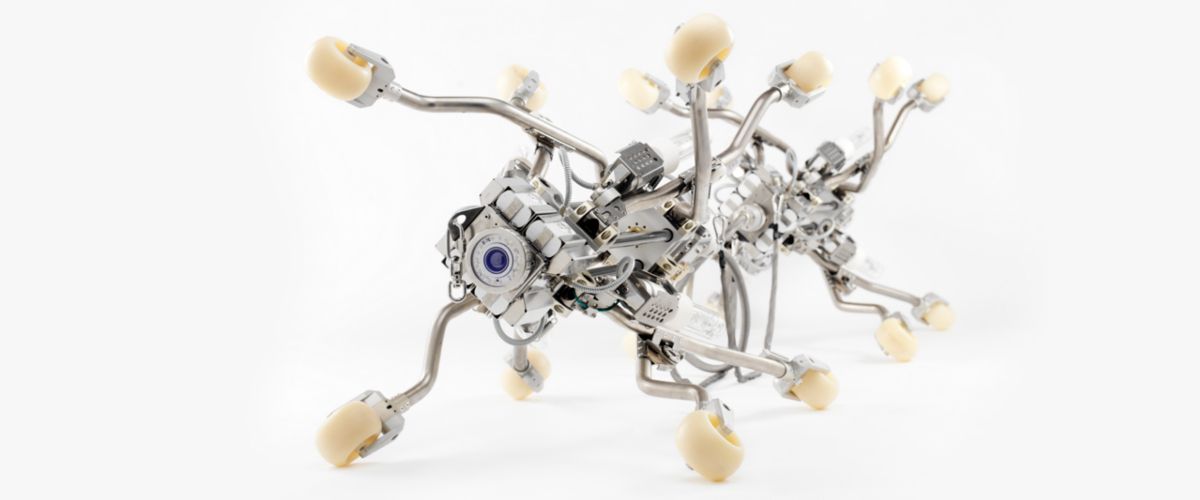

The name ProKASRO stands for progressive sewer rehabilitation robotic systems, signifying the company’s dedication to creating a tailored solution for sewer rehabilitation. Robots, systems for lateral intake rehabilitation and UV-Technology; ProKASRO is a full range manufacturer and supplier for sewer rehabilitation.

ProKASRO rehabilitation equipment restores sewers into perfect condition, alleviating the need for expensive and difficult open-cut methods. ProKASRO provides damage diagnoses and repairs that can carried out without excavation work, traffic obstructions or noise. Working within short rehabilitation timeframes ensures that it is not usually required to block off the sewer during rehabilitation work.

By using ProKASRO sewer rehabilitation equipment, the entire underground sewer system is safeguarded whilst maintaining ecological, hygienic and technical standards.

By using ProKASRO sewer rehabilitation equipment, the entire underground sewer system is safeguarded whilst maintaining ecological, hygienic and technical standards.

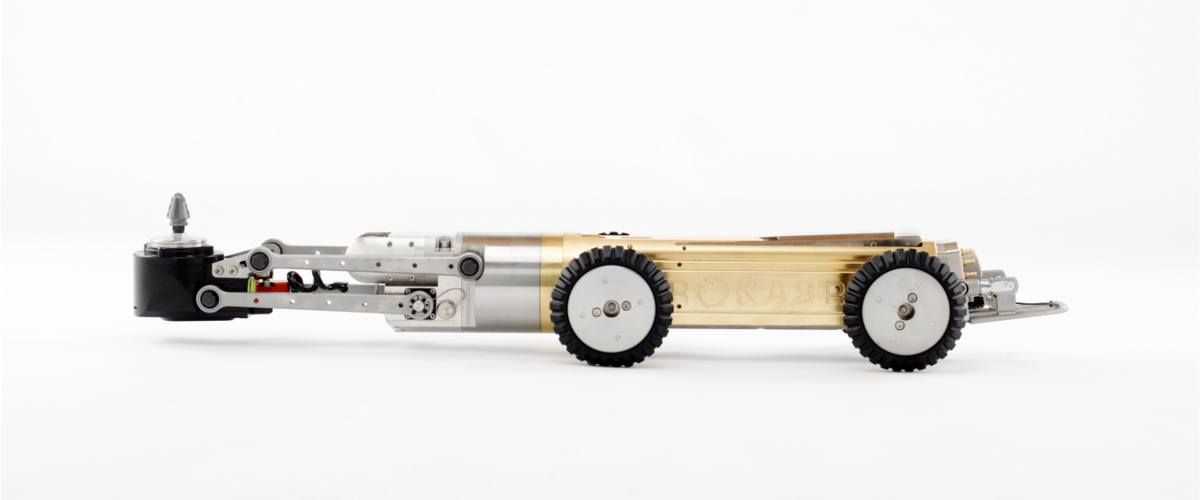

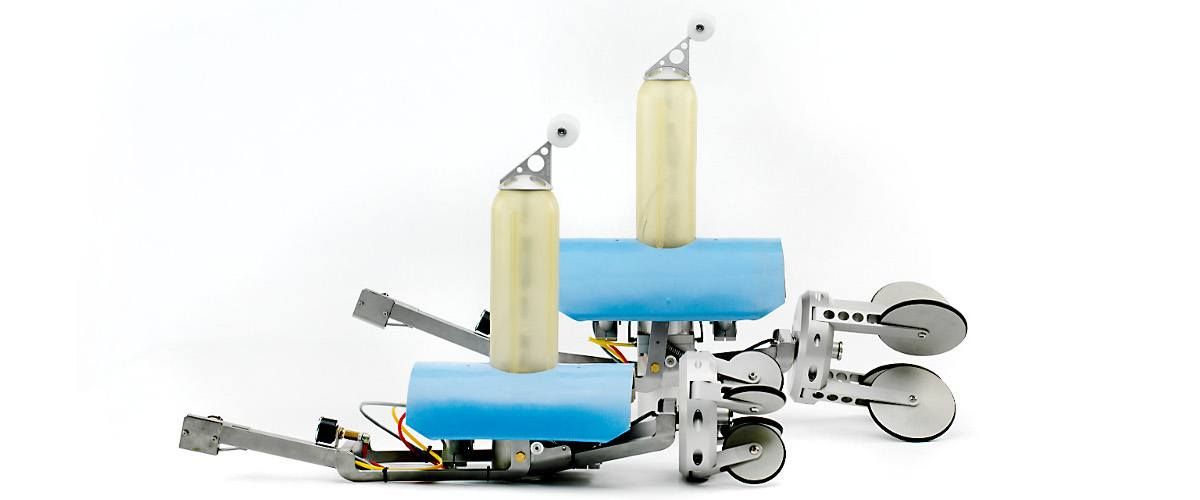

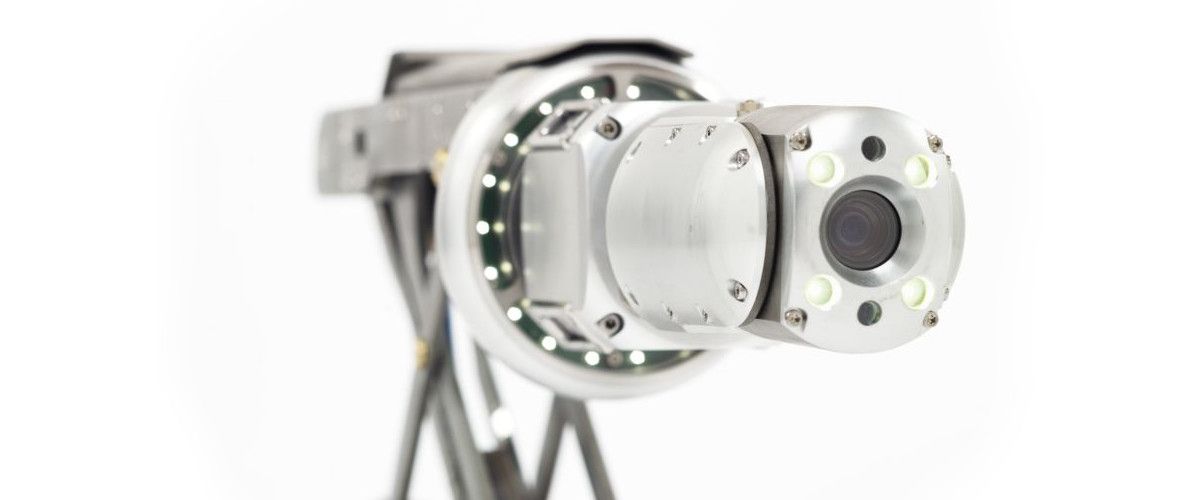

KASRO robot systems and systems for lateral intake rehabilitation are available for different pipe diameters from DN100 to DN1000 and can be combined together as required. This means that your preferred rehabilitation system can be tailored to suit your job. Various tool attachments permit the sewer robots to perform milling, grinding, filling, moulding and injection operations. They can also be used for positioning balloons and installation of top hat profiles and liners for lateral connections.

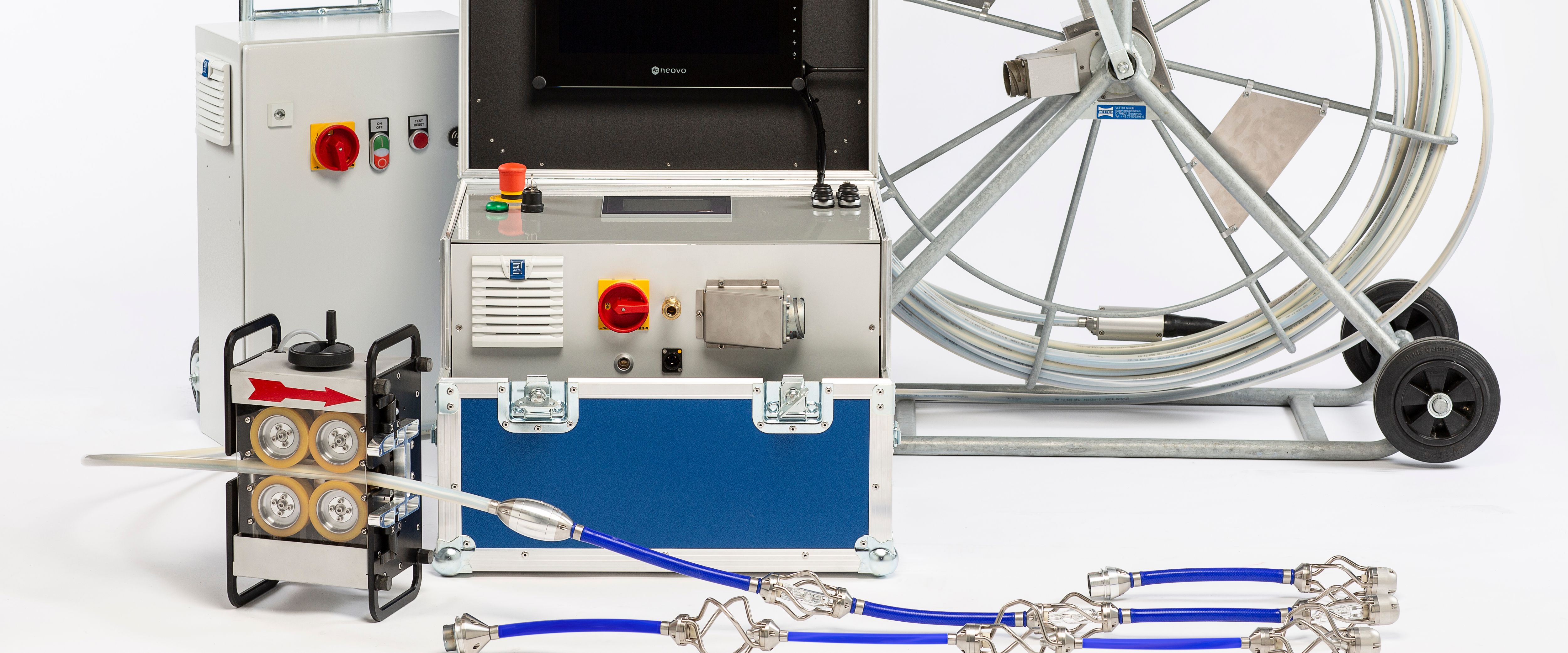

All rehabilitation work is managed and monitored from a rehabilitation vehicle that is individually designed and constructed to the costumer’s own preferences. On an optional basis transportable mobile control units are also available if preferred or required.

ProKASRO has the cure

ProKASRO is also the market leader within the field of UV curing Technology from DN150 to DN1000 – whether mobile or within a rehabilitation vehicle.

Manufacturing all products is performed 100 per cent in-house:

From the working robots and the UV-Technology, to the individual product ideas and advanced production.

New products for sewer rehabilitation are developed in-house and existing units are continuously developed and comprehensively tested. Products are manufactured and assembled component by component in our company-owned factory. Efficient channels of communication and integrated work processes guarantee the highest level of reliability of our products. 100 per cent made in Germany is an essential statement for ProKASRO.