Time is Cash, Time is Money

Time is Cash, Time is Money

- ProKASRO shifts into turbo-drive – UV-Curing-speeds at record level -

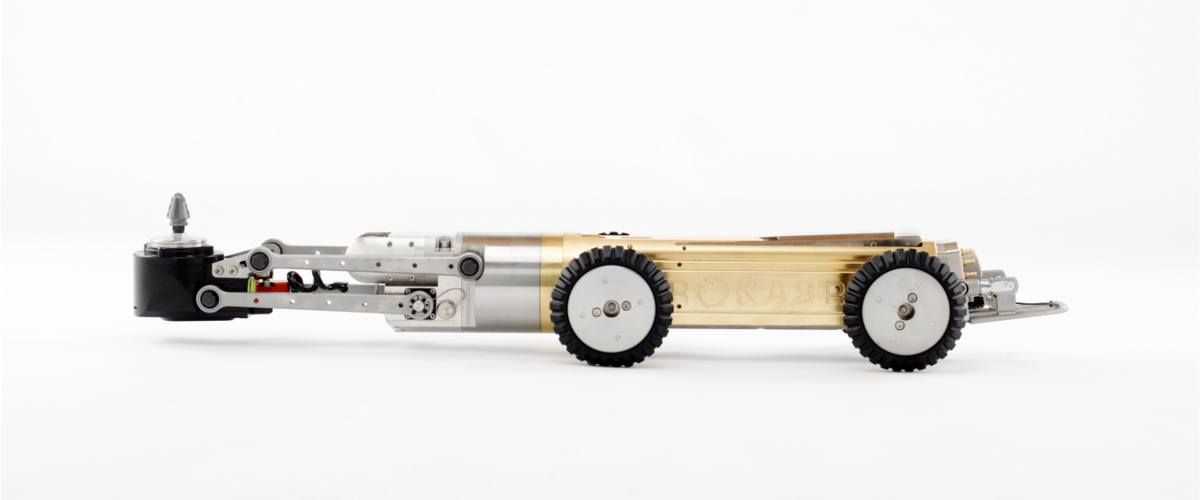

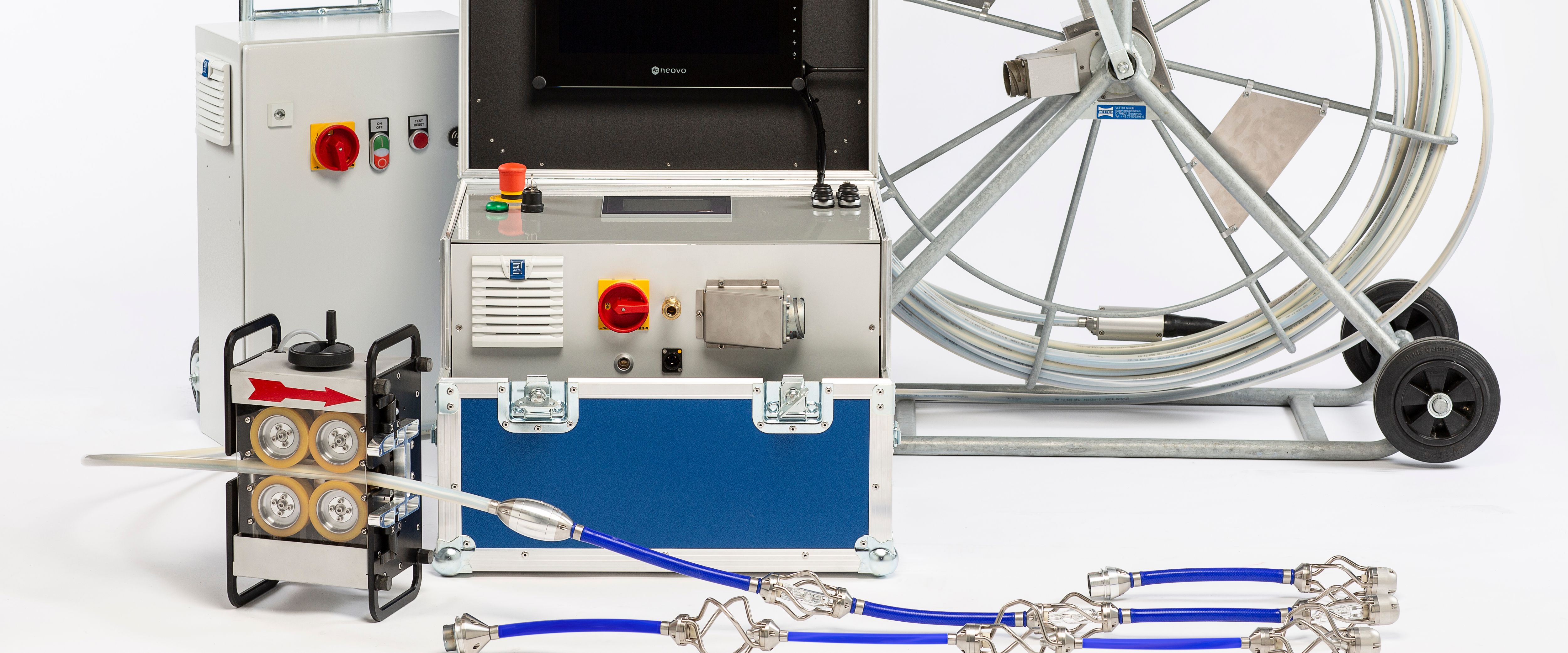

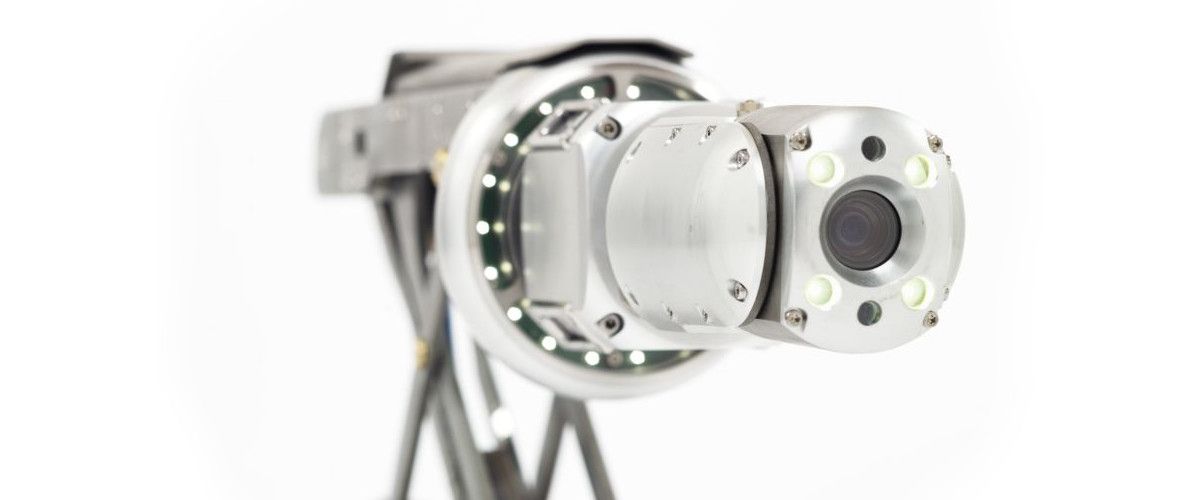

It’s now been two decades since, in 2003, ProKASRO Mechatronik GmbH expanded its product range to include KASRO UV Technology and became an international full-range supplier for complete sewer rehabilitation solutions. Innovation and the continuous evolution of existing technologies are central to ProKASRO’s philosophy, and it was this approach that led to a further promising development at the company in 2018.

It all began when ProKASRO received an enquiry from Poland that set the development of a new UV line in motion. The project called for an even higher-performing UV system than was available on the market at the time. The ProKASRO engineers took up the challenge and got down to work. The KASRO UV control unit and drum were re-engineered, produced and adapted to the new requirements. The end result was impressive: the KASRO POWER UV 36,000W system appeared to outperform everything available up until that point in every respect. In particular, this powerful system is predestined for large liners with thicker wa lls.

lls.

Investment instead of “fire restoration”

Then, in 2019, Swietelsky-Faber GmbH Kanalsanierung lost one of its UV systems due to a fire at the Leipzig branch. A fierce blaze caused by a short circuit in the truck damaged the system beyond repair. The high volume of business on the books meant that the system needed replacing as quickly as possible. However, the willingness to invest in new UV technology was not just a direct result of the fire: “profitable growth” is key to Swietelsky-Faber’s philosophy – and that means being prepared to invest in modern and forward-looking technology. The longstanding and positive business relationship between the two companies also played a part in the selection process, and Swietelsky-Faber decided to purchase a 36,000W POWER UV system from ProKASRO.

Although Swietelsky-Faber was already aware of the kind of performance that could be expected from this innovation, no curing tables from the liner manufacturers existed at the time. In principle the manager of the Leipzig brand, Mr Heil, was convinced by the fact that the curing speeds for the standard KASRO PROFESSIONAL UV systems were (and continue to be) listed in all the leading liner manufacturers’ manuals and meet the requirements of the external construction inspectors. After all, construction work can only be executed to the satisfaction of everybody involved when the pulling speeds of the light sources are specified and verified. Therefore, in order for the improved performance now available to be utilised in real-life situations on the construction site, it was vital to establish and validate the pulling speeds of the new system’s light sources.

The “Ferrari theory”

A round this time tough discussions took place between Uwe Reinhardt, managing director of ProKASRO Mechatronik GmbH, and colleagues from Swietelsky-Faber. Mr Reinhardt insisted that, as listed and confirmed by the liner manufacturers up until that point, the pulling speeds for the KASRO UV systems, and especially for the new POWER UV line, didn’t come close to reality and were in fact far too slow. This conviction was based on his many years of experience in the sewer rehabilitation sector and particularly in UV curing, which has made him a well-known and respected voice in the industry.

round this time tough discussions took place between Uwe Reinhardt, managing director of ProKASRO Mechatronik GmbH, and colleagues from Swietelsky-Faber. Mr Reinhardt insisted that, as listed and confirmed by the liner manufacturers up until that point, the pulling speeds for the KASRO UV systems, and especially for the new POWER UV line, didn’t come close to reality and were in fact far too slow. This conviction was based on his many years of experience in the sewer rehabilitation sector and particularly in UV curing, which has made him a well-known and respected voice in the industry.

This was also clear to Swietelsky-Faber, and the company immediately placed an order for two more POWER UV systems.

Nevertheless, the time had come to conduct a large-scale field trial and test the actual pulling speeds under real-life construction site conditions. Because of the agreement between the two companies, it was clear to both sides: in order to deliver dependable data for the curing tables, ProKASRO needed to collaborate with a UV-construction company like Swietelsky-Faber.

No time was wasted: Mr Reinhardt’s explanations of the huge potential for increasing the pulling speeds had already convinced Mr Heil. However, words alone are not enough when such a complex issue is involved: now, with the collaboration of all the relevant colleagues at Swietelsky-Faber, the mission was to collect verified data so that it could be listed as a guarantee in the liner manufacturers’ manuals.

collect verified data so that it could be listed as a guarantee in the liner manufacturers’ manuals.

Mr Heil summed the situation up with a fitting comparison: “What good is owning a Ferrari if the official speed limit means I’m not allowed to drive it faster than 100km/h?” The aim was therefore to eliminate the imaginary “throttle” and allow the “Ferrari” to make the most of its potential. The concrete planning phase could begin. Together with ProKASRO, Swietelsky-Faber pulled out all the stops and used its influence as a major customer to win the liner manufacturers over. Since then, the measurements and trials necessary to ascertain the actual pulling speeds possible with the POWER UV systems have been conducted on an enormous scale.

Test 1, Test 2, Test 3

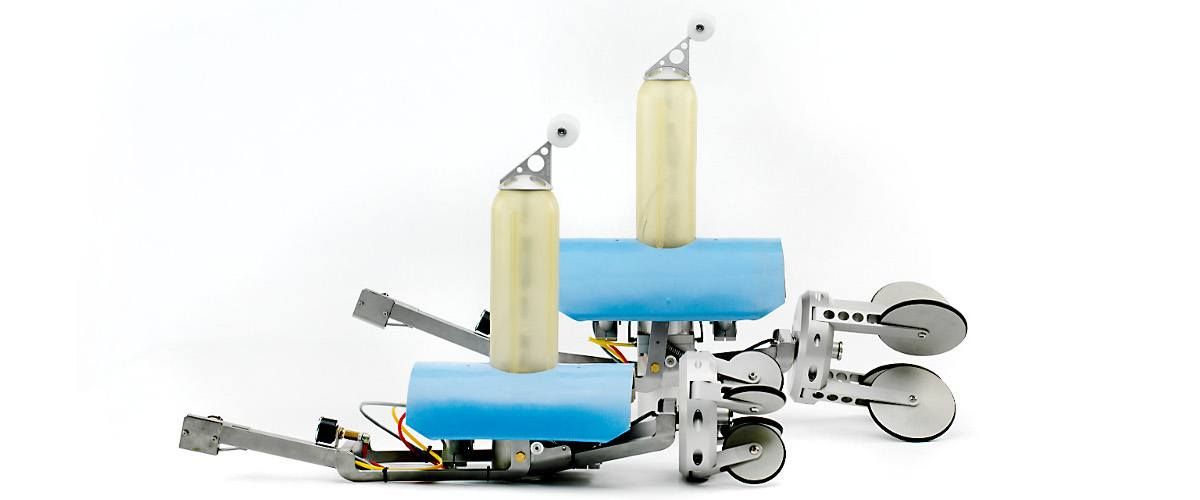

The first step involved precise measurement of the POWER light sources in order to determine their intensity and calculate the theoretical speeds. The next stage was to construct the first above-ground trial setups. Swietelsky-Faber made its new POWER UV systems available for the purpose. In order to obtain differentiated and reliable results, liners with various diameters were cured using different POWER UV-light cores. The mechanical properties and residual styrene of the material samples taken after curing were meticulously tested – with promising results. The two liner manufacturers involved in these initial tests then produced provisional curing speed tables.

A direct comparison of the test results clearly showed the impressive effects of increasing the energy input and thus also the pulling speeds. The performance topped even the high expectations prior to testing:

|

Liner DN 1000 |

ProKASRO 3 x 4 x 1000W triple core |

ProKASRO 4 x 4 x 1000W quadruple core |

ProKASRO 4 x 4 x 2000 W quadruple core |

|

Wall thickness 7mm |

85-95cm/min |

110-130cm/min |

195-220cm/min |

|

Wall thickness 10mm with combined curing |

60-95cm/min |

95-110cm/min |

160-195cm/min |

|

Liner DN 1000 |

ProKASRO 2 x 6 x 1000W triple core |

ProKASRO 3 x 6 x 1000W triple core |

ProKASRO 3 x 6 x 2000W triple core |

|

Wall thickness 7mm |

80-85cm/min |

130-140cm/min |

255-270cm/min |

|

Wall thickness 10mm with combined curing |

80-90cm/min |

130-145cm/min |

250-265cm/min |

With the KASRO 4 x 4 x 2000W core, the pulling speed could be almost tripled as compared to the 3 x 4 x 1000 W core, thus reducing the curing time by one third. The KASRO 3 x 6 x 2000W Jumbo core could also be travel at three times the speed as compared to the KASRO 2 x 6 x 1000W Jumbo double core.

In order to verify the experiments under even more realistic conditions, Swietelsky-Faber implemented a third step: after consultation with the test lab and principals, the data obtained so far was applied on site during actual construction projects. This resulted in countless large-profile liners being cured with the KASRO POWER UV system using the newly established and much faster pulling speeds. The SBKS test laboratory headed by Prof. Dr. Jörg Sebastian conducted the measurements necessary to check and verify the established pulling speeds. The mechanical values obtained after curing – particularly the gratifyingly low residual styrene content – exceeded all expectations and confirmed what was already clear: the new KASRO POWER UV rehabilitation system is currently the highest-performing light curing system on the global rehabilitation market.

On-the-job safety = employee satisfaction

However, the benefits of the faster pulling speeds are not limited to cost savings and the increased efficiency of the construction work. In terms of on-the-job safety, they also represent a major step towards employee-friendly working conditions and help relieve the pressure on the construction team. In recent years, both construction sites and liners have become bigger and bigger, making installation an increasingly time-consuming process. Not infrequently, this results in the working day of a UV systems crew exceeding the legal directives. Faster pulling speeds can reduce daily working time by several hours, especially in the case of large-profile projects. That brings the ultimate goal of a moderate workload and regular working hours within reach – and given the current challenges associated with finding skilled employees, that represents a huge benefit for employers when it comes to recruit ing.

ing.

DN2000 in turbo mode

The DN2000 construction work carried out in March 2021 at a site in Reggio Emilia, Italy, is a prime example. Unprecedented anywhere in the world, the project marked a major milestone in sewer rehabilitation and for ProKASRO itself. Here too, the new POWER UV system was deployed. By using 2,000W UV bulbs instead of 1,000W bulbs, it was possible to achieve a maximum output of 36,000 watts, resulting in drastically increased pulling speeds and therefore much shorter curing times.

The DN2000 construction work carried out in March 2021 at a site in Reggio Emilia, Italy, is a prime example. Unprecedented anywhere in the world, the project marked a major milestone in sewer rehabilitation and for ProKASRO itself. Here too, the new POWER UV system was deployed. By using 2,000W UV bulbs instead of 1,000W bulbs, it was possible to achieve a maximum output of 36,000 watts, resulting in drastically increased pulling speeds and therefore much shorter curing times.

After preparing the site by installing the liner and packer, calibrating the liner and deploying the KASRO POWER UV Triple Jumbo core, it was possible to cure the 164-metre-long, 22-tonne liner in the incredible time of just four hours. It was a record achievement for all those involved and for the UV technology – and was witnessed by staff from Swietelsky-Faber who, in light of the planned investments, had travelled to the site to see what the system was capable of for themselves.

But there is still a lot to do, and this UV innovation is far from the final step. With its 36,000W system, ProKASRO is one step closer to achieving the overriding goal of reducing the residual styrene in the liner to less than 1%. The next development is already in the pipeline and involves using special sensor technology and an infrared controller for precise measurement of the laminate temperature. Together, KASRO UV technology and Swietelsky-Faber have made meaningful progress towards resolving the understandable controversy surrounding the residual styrene content of cured liners.