IKARUS and new one-component UV resin on tour in Turin

The rehabilitation of small pipe diameters is often associated with difficult-to-reach accesses. This was also the case in the beginning of October 2020 for our customer Blueco in Turin. The entrance was on the roof of an eight-story residential complex. For weeks, ailing downpipes led to serious water damage with damp walls and ceilings in the adjacent residential units. Since first attempts at repair with alternative rehabilitation methods failed, the IKARUS UV house connection system was used to repair the damage as quickly as possible.

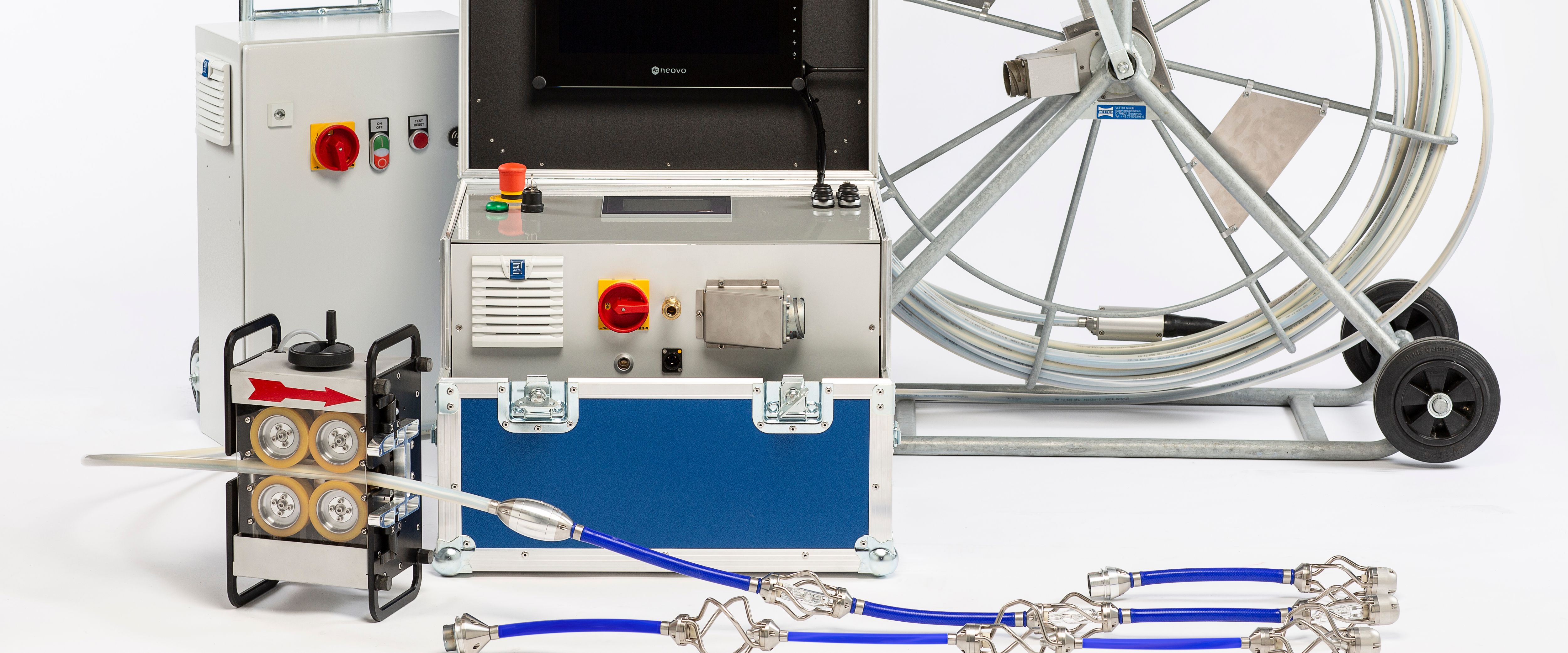

At the end of October, two ProKASRO service technicians were on site and carried out the renovation together with Blueco. A new light-curing one-component epoxy resin was used for curing. The big advantage of the new resin is, as the name suggests, it no longer has to be mixed on site. Mixing errors and air inclusions are avoided and make it particularly stable. The shelf life is

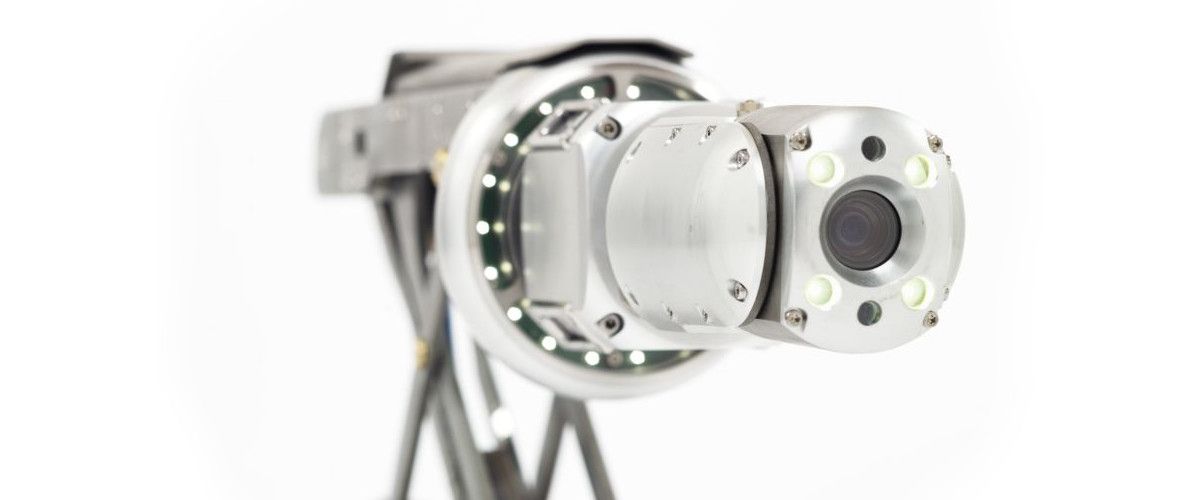

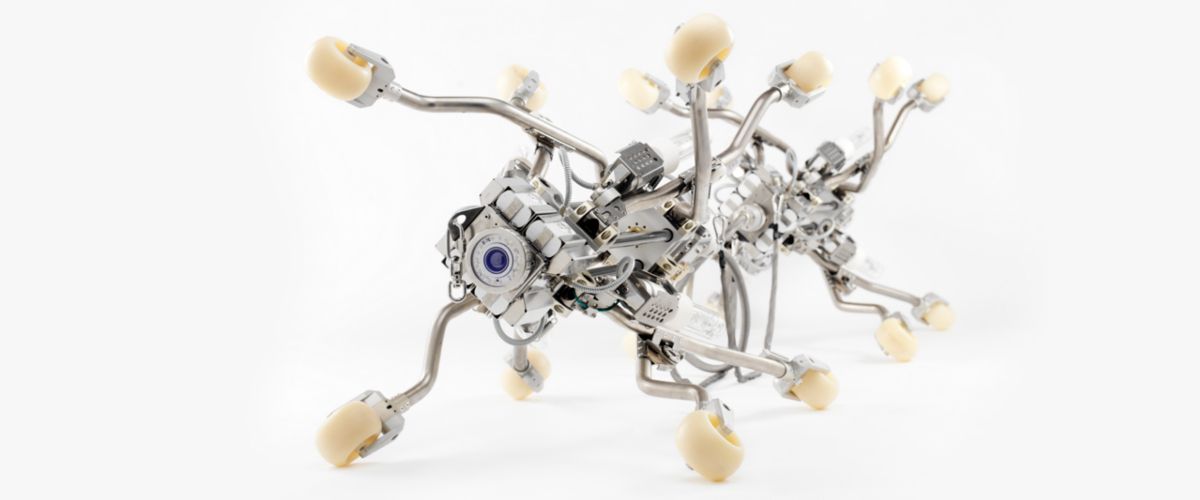

At the end of October, two ProKASRO service technicians were on site and carried out the renovation together with Blueco. A new light-curing one-component epoxy resin was used for curing. The big advantage of the new resin is, as the name suggests, it no longer has to be mixed on site. Mixing errors and air inclusions are avoided and make it particularly stable. The shelf life is  particularly long with a storage stability of at least six months. This first light-curing epoxy resin cures much faster than conventional epoxy resin. It is also very user-friendly due to the elimination of pot life. Unlike with two-component resins, the application technicians are not under extreme time pressure to install the liner within a given short pot life. This way, careless mistakes and liners that have hardened before the inversion and are therefore unsuitable can be avoided. Compared to conventional rehabilitation methods, you can also see the result before the curing process. The camera mounted on the light chain shows whether the desired wrinkle-free result has been achieved in the pressurized liner. If not, the liner can easily be removed again and re-inverted.

particularly long with a storage stability of at least six months. This first light-curing epoxy resin cures much faster than conventional epoxy resin. It is also very user-friendly due to the elimination of pot life. Unlike with two-component resins, the application technicians are not under extreme time pressure to install the liner within a given short pot life. This way, careless mistakes and liners that have hardened before the inversion and are therefore unsuitable can be avoided. Compared to conventional rehabilitation methods, you can also see the result before the curing process. The camera mounted on the light chain shows whether the desired wrinkle-free result has been achieved in the pressurized liner. If not, the liner can easily be removed again and re-inverted.

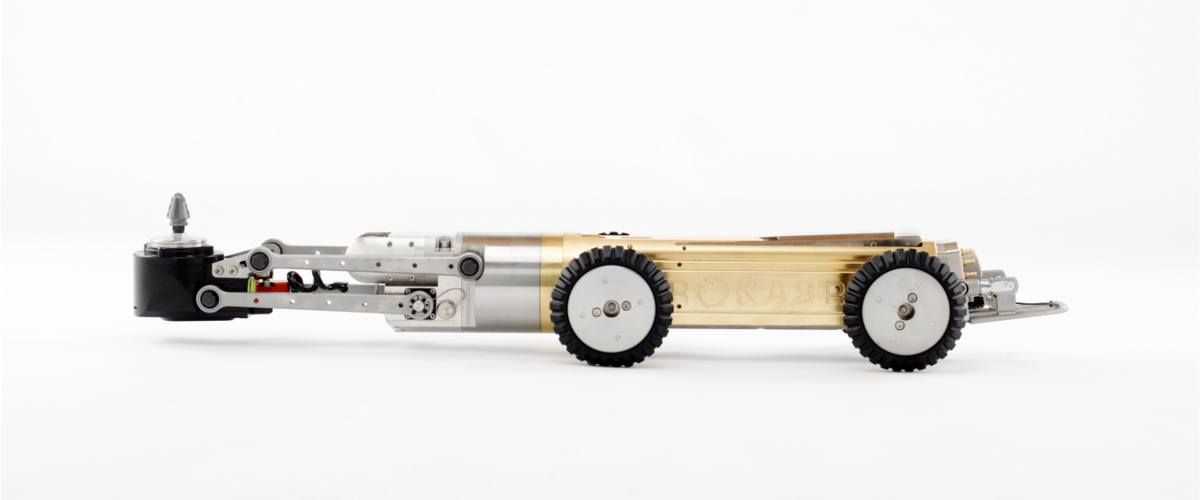

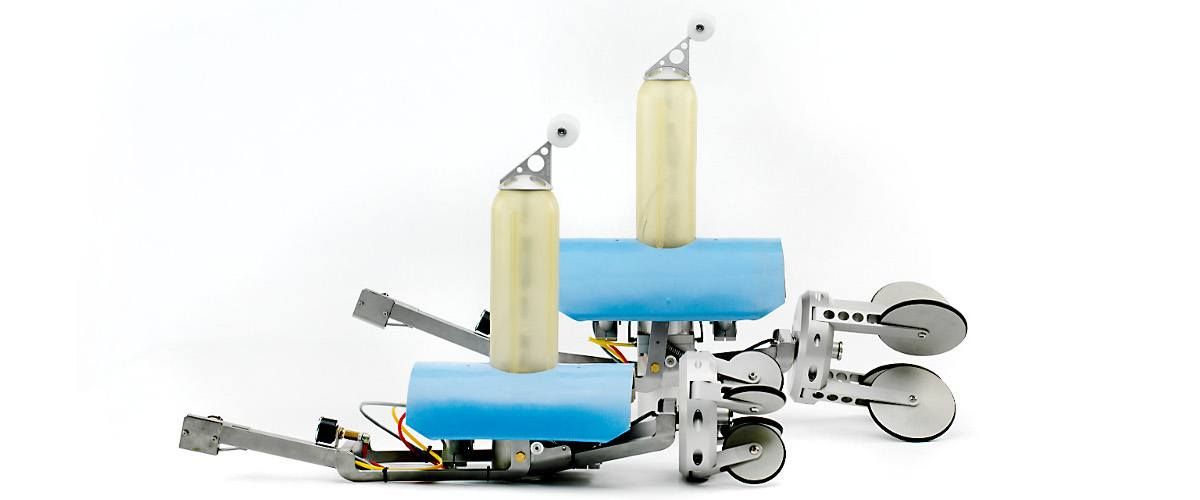

The difficulties with this project were not only the multiple dimensional jumps from DN 95 to DN125 as well as many branches, but also two successive bends with 67° on the downpipe after a 27m stretch. The solution was the bend-capable light chain IKARUS with a lamp power of 3 x 200W and the used 3D liner which could flexibly adapt to the given changing diameters thanks to its elasticity. The overall package of IKARUS, 3D Liner and the new one-component resin enabled a successfully completed construction site and led to the complete satisfaction of clients and residents.