Newsletter 02/ 2020 - EN

*** ProKASRO is a pioneer with Stage V generators ***

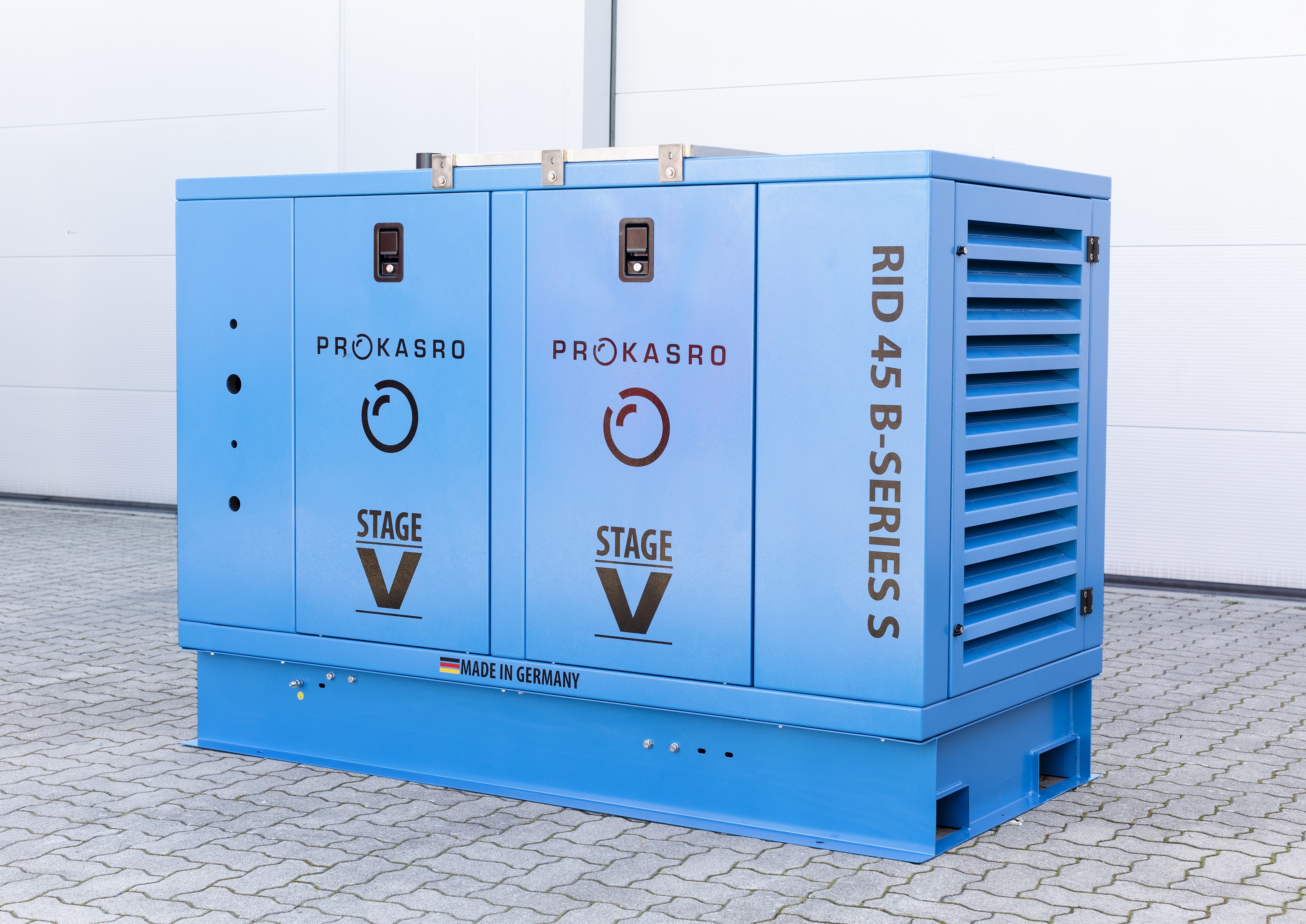

From 2020, the particle emissions from tractors, combine harvesters and construction machinery will have to be reduced further and the emissions standards will have to be stricter. This is provided by the new EU Stage V exhaust gas regulation, which the European Parliament passed by a large majority at the beginning of July 2016. Accordingly, from 2020 at the latest, all engines that are brought onto the market must comply with the Stage V limit values. According to the emissions legislation for mobile machines (Stage V), the engines with the emission standard IIIA have a transition period until early 2021.

ProKASRO is the first company on the market worldwide to offer and install generators with the corresponding Stage V specifications. Since July 1st, 2020 we have been able to comply with the EU emissions standard for the 45kVA, 80kVA and 100kVA generators and are also ready to deliver.

A generator manufacturer was commissioned in early 2020 to develop a generator series in accordance with the new EU guidelines and specifications. By using catalysts and adding AdBlue (starting at 80 kVA), the exhaust gases are treated in a more environmentally friendly way and the CO2 and fine dust emissions are reduced. Our first Stage V generator was successfully commissioned in July 2020 in collaboration with the engine and generator manufacturer in ProKASRO design. Our customer Mr. Laurent BAUER from TELEREP France Agence Méditerranée receives the first brand new system in July and is therefore also a pioneer in our industry with the latest technologies.

Despite the new structure, the power of the power generators remains almost on a par with comparable older generators, which have a greater impact on the environment and are no longer officially approved from 2020 on. With a system from ProKASRO, you can easily continue your construction site without fear of violating the new regulation. For us as a company, environmental protection and at the same time the needs of our customers are our top priority and therefore do everything we can to combine one with the other.

Here are some advantages at a glance:

- MADE IN GERMANY in ProKASRO design

- Compact size

- Low vibration construction

- Very easy to use

- Rust and UV-protected powder coating

*** New service stations in Germany and China ***

ProKASRO Service Mitte

After the opening of the US service station "ProKASRO Services USA" in Colorado in early 2018 and the new service base in France "PK Sud" at the end of 2019, we are now opening two further repair locations in 2020. On the one hand, ProKASRO Service Mitte GmbH in Saxony-Anhalt welcomes our customers from the north and the center of Germany. On the other hand, PSM is predestined to process customer inquiries and service orders from Eastern Europe due to its geographical location. In Poland, the Czech Republic and Slovenia in particular, we were able to win some new customers and are now looking forward to responding to inquiries particularly quickly. Our colleagues at PK Mitte can be reached as follows for any repair or service cases:

ProKASRO Service Mitte GmbH

Priemitzstraße 7

06184 Kabelsketal

+49 0341 91981-347

ProKASRO Maintenance and Service Point Peking

ProKASRO Maintenance and Service Point Beijing

Furthermore, a new service office under the name "ProKASRO Maintenance and Service Point" will also open in Beijing / China from September 2020, which will initially only take care of repairs in and around Beijing. All of China is to be served in the future. The office and workshop are currently in full swing to be able to open on time in fall this year. In November 2019, ProKASRO Managing Director Uwe Reinhardt met the Chinese colleagues on site in Beijing to discuss the exact structure of the workshop. This guarantees that the most advanced tools on the market are available. Another location in Asia, in addition to our partner Nitto in Japan, enables an even faster response to repair requests and saves long and expensive delivery times from Germany. In addition, trained service technicians are on site and can serve customers faster and instruct them in the KASRO systems.

*** 20 years ProKASRO special! ***

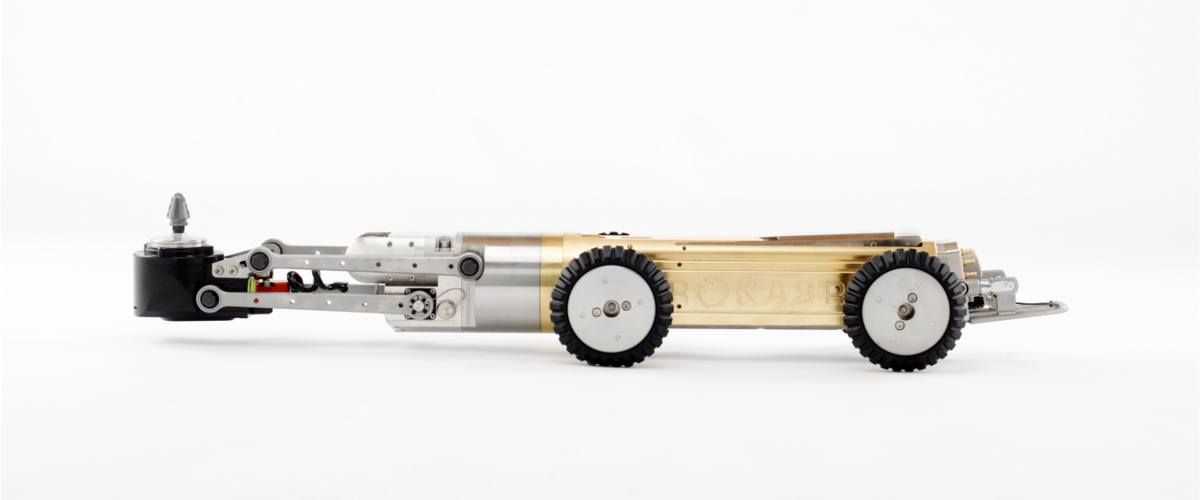

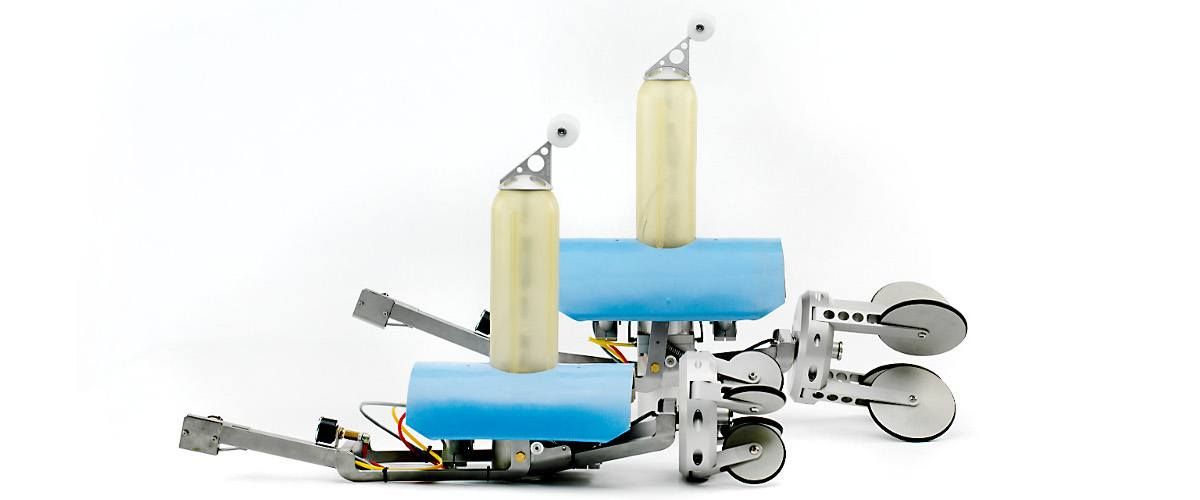

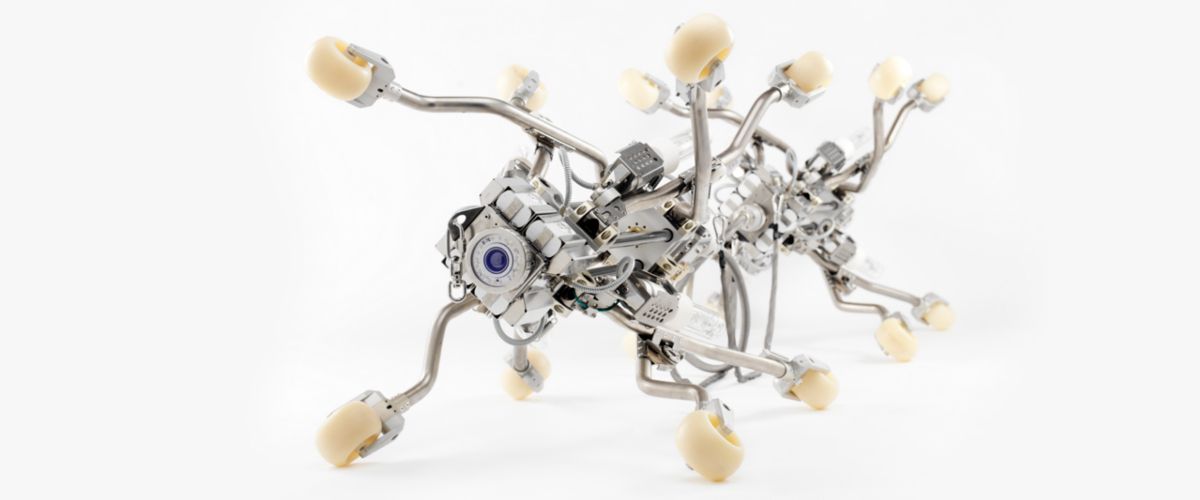

On the occasion of this year's company anniversary, we have a special offer from ProKASRO. As a thank you for 20 years of customer loyalty to KASRO sewer rehabilitation technology, a limited number of electric milling vehicles with a new SUPERIOR extension with HYBRID drive are being built, and the price is extremely attractive with the absolute special price of 222.222€. The ten brand new renovation systems, installed in 6t Ivecos Daily (carrier vehicle is included in the price!), Are small and maneuverable. Construction sites that are difficult to access can thus be reached more easily. In addition to the powerful 4.0 KASRO electric robot (included in the price), the system can also be easily extended to all lateral rehabilitation systems. The turnkey van has special highlights:

On the occasion of this year's company anniversary, we have a special offer from ProKASRO. As a thank you for 20 years of customer loyalty to KASRO sewer rehabilitation technology, a limited number of electric milling vehicles with a new SUPERIOR extension with HYBRID drive are being built, and the price is extremely attractive with the absolute special price of 222.222€. The ten brand new renovation systems, installed in 6t Ivecos Daily (carrier vehicle is included in the price!), Are small and maneuverable. Construction sites that are difficult to access can thus be reached more easily. In addition to the powerful 4.0 KASRO electric robot (included in the price), the system can also be easily extended to all lateral rehabilitation systems. The turnkey van has special highlights:

- Hybrid DC charging generator 12kW

- 900Ah GEL deep cycle batteries

- 7kW inverter (peak 15kW)

- Charger for quick charging via generator or external power supply wide range

- 10’’ touch display

- Generator autostart

- Maintenance battery switch

- Can-Bus cabling for remote maintenance

This special applies to “First come first serve!” So: be quick and secure your brand new electric milling vehicle. Because one thing is certain. This price will not be available again for such an expansion!

*** Mit sauberer Technik für eine saubere Umwelt ***

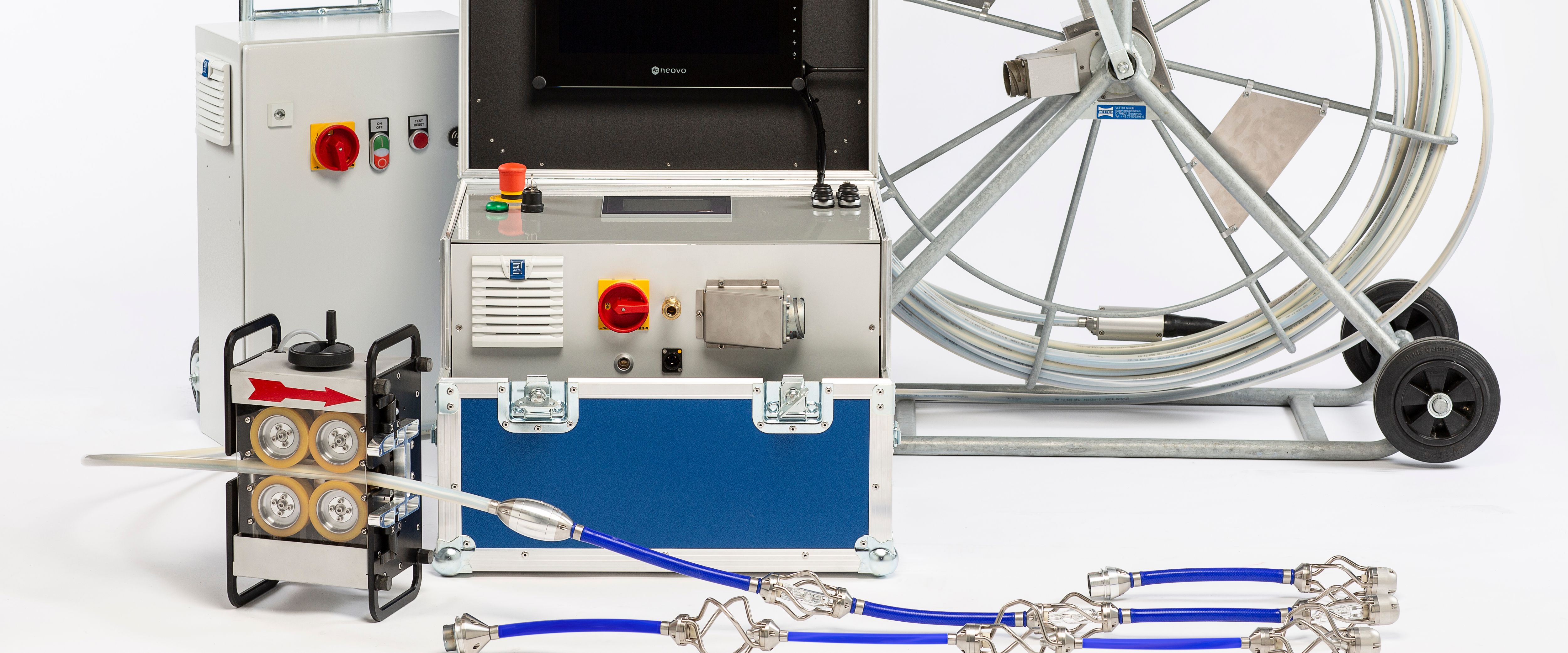

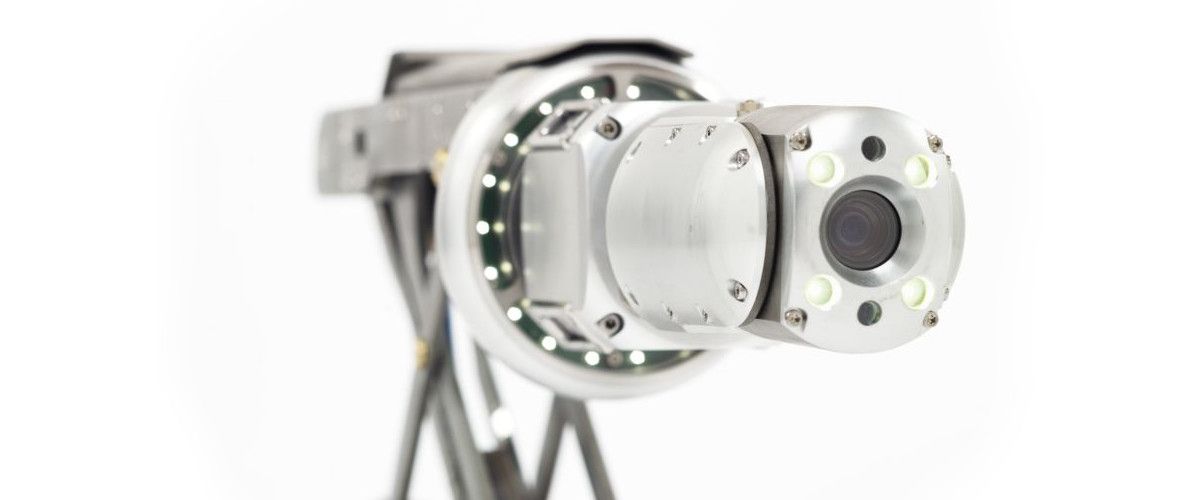

EXPERT 2.0 - that's the name of the new vehicle type from ProKASRO. Comfort and environmental protection are particularly important here. An almost ground-level entry into the vehicle via the rear door with a staircase integrated in the vehicle enables the plant operators to easily and safely access the working machine. The roof, which can be extended electrically via remote control, offers additional comfort and protects the operators from rain and sun. In addition, the included working robots can be stowed safely in practical drawer boxes. This innovative system with triple hybrid power supply is operated entirely electrically by special battery packs and solar panels. The included generator only serves to charge the built-in batteries. The system is therefore a completely self-sufficient, electrically operated system with the following highlights:

EXPERT 2.0 - that's the name of the new vehicle type from ProKASRO. Comfort and environmental protection are particularly important here. An almost ground-level entry into the vehicle via the rear door with a staircase integrated in the vehicle enables the plant operators to easily and safely access the working machine. The roof, which can be extended electrically via remote control, offers additional comfort and protects the operators from rain and sun. In addition, the included working robots can be stowed safely in practical drawer boxes. This innovative system with triple hybrid power supply is operated entirely electrically by special battery packs and solar panels. The included generator only serves to charge the built-in batteries. The system is therefore a completely self-sufficient, electrically operated system with the following highlights:

- Whisper Power DC generator system (3-cylinder Kubota D722, 10 kVA 300 A / 28.4 volts

- 2 x 24 volt charger

- Inverter 24 volts, 7 kVA

- Battery bank 19800 Ah (12 gel power 2V cells with 1650Ah each)

- Solar system 1710 watts (6 x 285 W Pmax)

- the power is fed into the system during generator operation; the remaining energy charges the battery bank

- Battery life up to 6h at full capacity and automatic generator start

Rossaro Kanaltechnik picked up such a system in July this year and is already in use. Rossaro was founded in 1997 and belongs to the Rossaro group in Aalen Württemberg.

ProKASRO was founded more than two decades ago and since then Rossaro Kanaltechnik has been a satisfied and loyal customer of the Karlsruhe based manufacturer. ProKASRO currently provides the largest proportion of the company's working machines with four rehabilitation vehicles and one inliner system.

The company's slogan: "We offer ecologically and economically professional solutions" is made visible with the new rehabilitation vehicle from ProKASRO.

The rehabilitation robots are driven entirely electrically, and the batteries are supplied by photovoltaic modules on the roof of the vehicle. The project manager for sewer rehabilitation Mr. Sven Coumont emphasizes that these are sufficient to operate the vehicle independently for at least six months a year. The results are low diesel consumption and minimal emissions – so, clean technology for a clean environment!

The plant operator Stefan Schmidt is enthusiastic about the quiet workplace, where no noise and no waste heat from a generator or compressor makes working uncomfortable.

The milling and lateral intake rehabilitation techniques that have been used and tested for years mean that reliable and faultless work can be expected.