KASRO Goliath goes New York

bi Umweltbau August 2017

Two years ago, the company Entech from Closter was confronted with a construction site in the New York borough of Queens that posed a large challenge to man and machine.

Initial situation:

High-rise buildings in New York are usually erected on pillar foundations to anchor them in the low-lying bedrock prevailing there. This method is to prevent high and at the same time heavy skyscrapers from subsiding.

KASRO hydraulics container in front of the New York SkylineDuring a recent incident, sewer pipes buried in the ground were inadvertently drilled into and damaged during pillar drilling work. When the foundations were filled with high-strength foundation concrete, the tapped sewer pipes were inadvertently also filled. 40 m of main sewer with a diameter of DN 400 were affected during the construction of the high-rise building.

KASRO hydraulics container in front of the New York SkylineDuring a recent incident, sewer pipes buried in the ground were inadvertently drilled into and damaged during pillar drilling work. When the foundations were filled with high-strength foundation concrete, the tapped sewer pipes were inadvertently also filled. 40 m of main sewer with a diameter of DN 400 were affected during the construction of the high-rise building.

Once this calamity had been discovered, the city of New York asked the company Entech to attend to the construction site and to free the pipes from the concrete. The company had a shot at different methods of removing the concrete:

First, under the direction of Geno Camali, Entech tried to strip the concrete by means of a flushing vehicle and a chain spinning head. However, these endeavours were not crowned with success and another solution had to be found. Next a sewer cutter was used but only enabled extremely slow and little satisfying progress to be made. It was only possible to remove 2 cm of concrete per day.

Daniel Lefkowitz, Deputy Chief, NYC Environmental Protection: "We had a situation in Queens, New York, when a DN 400 combined sewer that served as important overflow pipe was filled with concrete, causing a severe sewer backup for the neighbourhood. We tried various milling machines powered by water pressure, and air pressure. However, the above equipment proved to be relatively ineffective and time consuming."

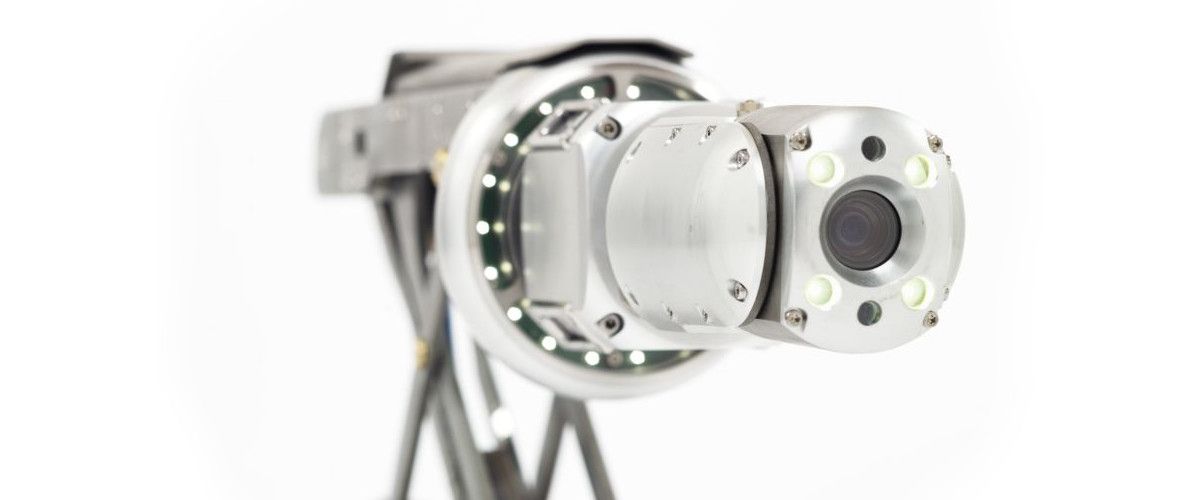

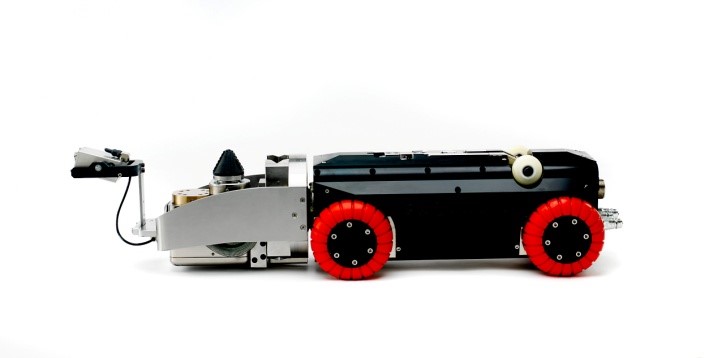

At this point, ProKASRO entered the scene for the first time and introduced its 1.7 electric robot, which was shortly afterwards replaced by the more powerful 4.0 electric robot. This proved a lot more successful than any of the other techniques applied before. Nevertheless, a progress of 7.5 cm per day still was not the ideal solution for removing the concrete smoothly and completely.

Subsequently, Entech took a new line of approach and tried to work through the concrete-filled sewer with a water milling cutter operating at maximum pressure. However, this equipment was not able to surpass the success of the ProKASRO 4.0 robot. In addition, with 25,000$ per month, the costs for this system were far from affordable.

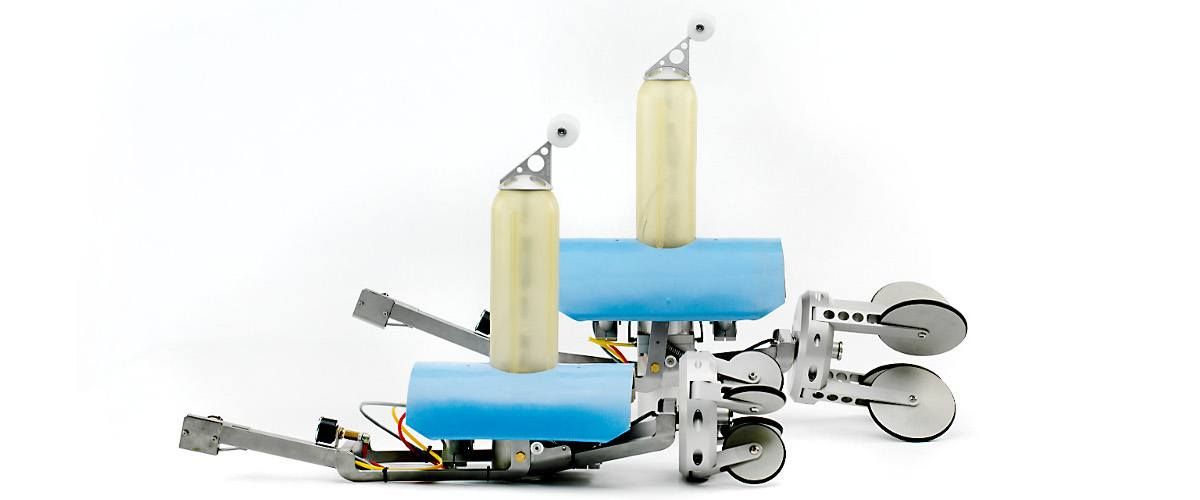

Einblick in das noch zu 60% mit Beton gefüllte RohrA much better and more effective solution had to be found. A solution that would not require any excavations and that would powerfully set to work inside the sewer. When Geno Camalis visited the company ProKASRO in Karlsruhe, Germany, the mechatronics firm hit on the idea of using its "Goliath system" for the New York construction site. The system consists of a hydraulic milling machine with above-average milling performance, which for this particular case was equipped with special milling heads provided by Schneider Diamantwerkzeuge.

Einblick in das noch zu 60% mit Beton gefüllte RohrA much better and more effective solution had to be found. A solution that would not require any excavations and that would powerfully set to work inside the sewer. When Geno Camalis visited the company ProKASRO in Karlsruhe, Germany, the mechatronics firm hit on the idea of using its "Goliath system" for the New York construction site. The system consists of a hydraulic milling machine with above-average milling performance, which for this particular case was equipped with special milling heads provided by Schneider Diamantwerkzeuge.

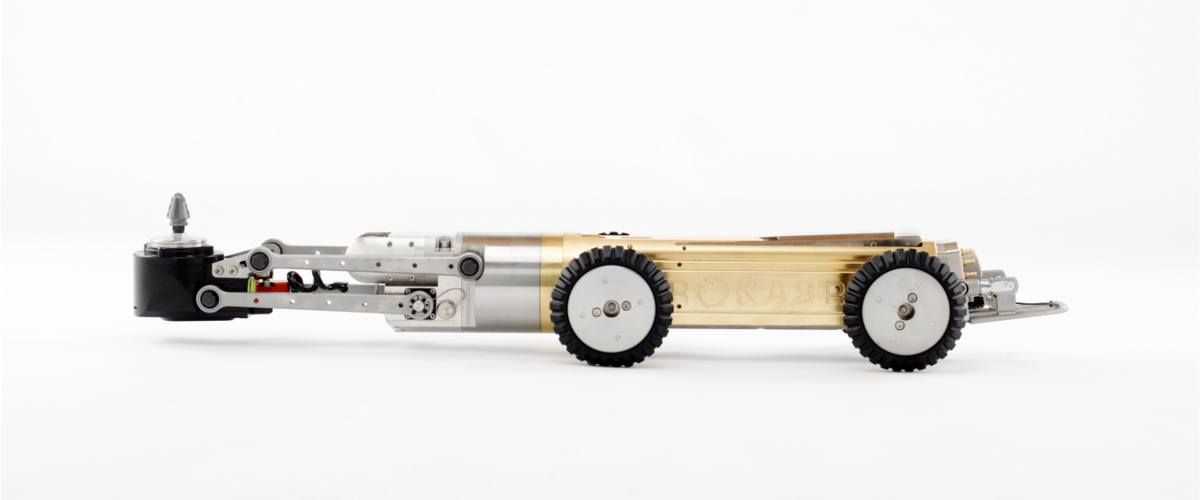

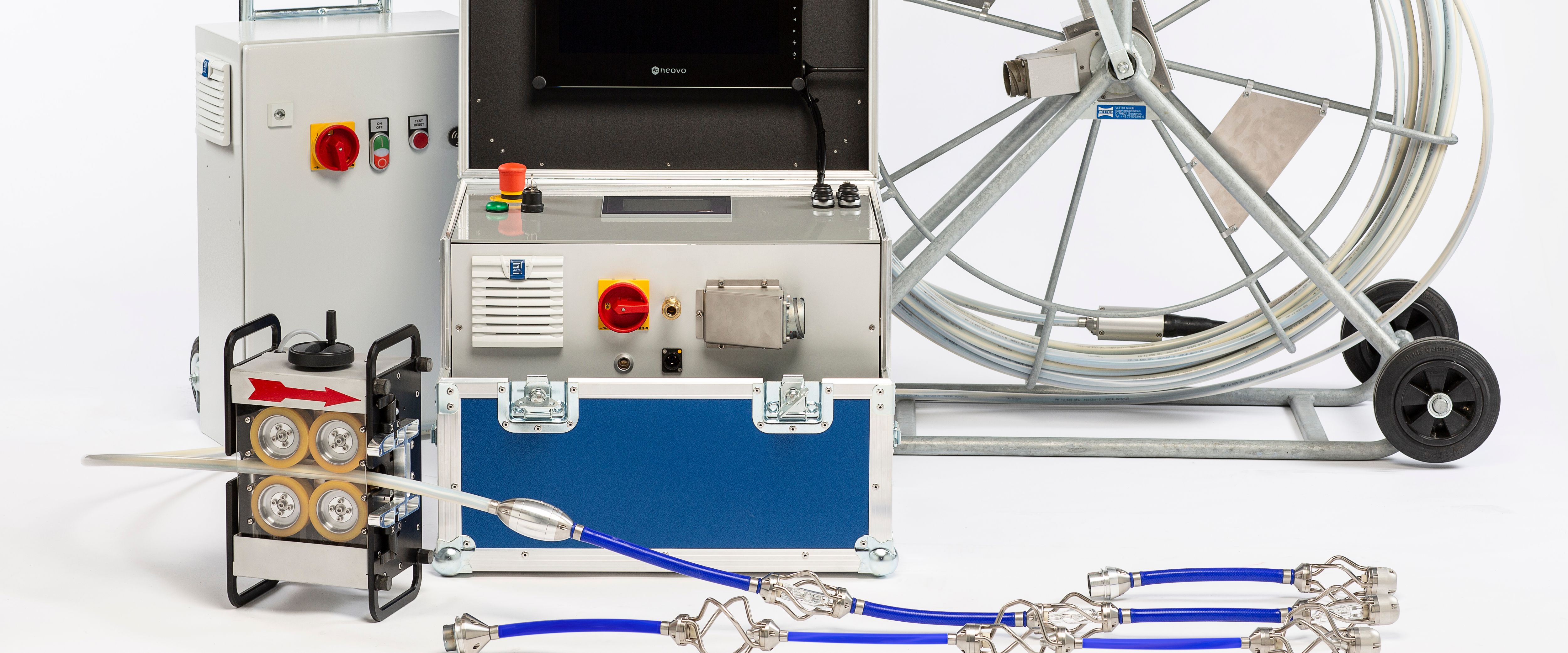

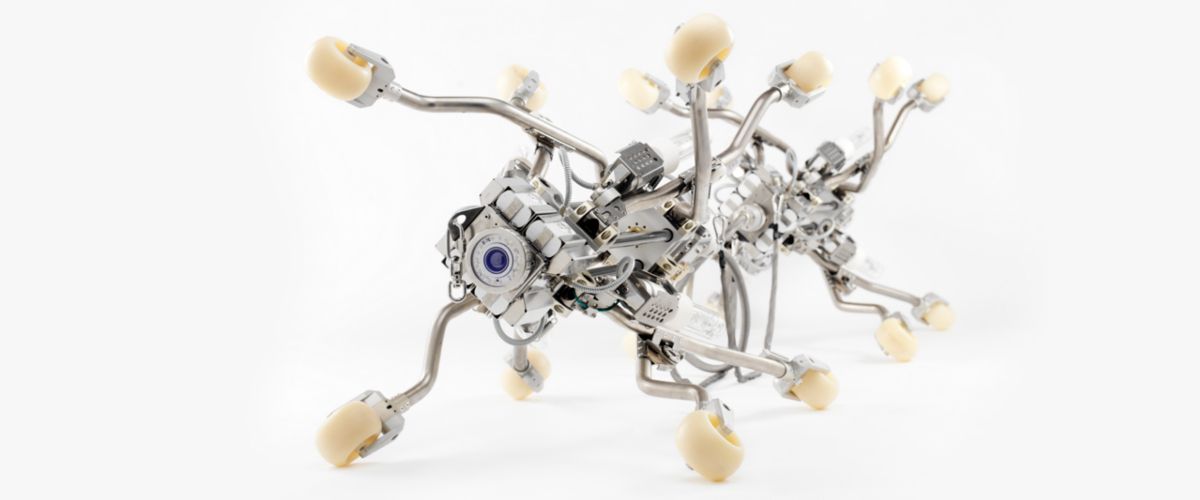

Der KASRO Hydraulikroboter "Goliath" von DN 250-600 mit 5kW FräsmotorThis system was made available to Entech as container solution under the direction of project manager Holger Müller from ProKASRO. Its efficiency in this special case was going to be tested in the USA within the scope of a pilot project. In his own words, Mr Camali had been looking for suitable equipment all over the world and had eventually found what he was looking for at the manufactory in Karlsruhe. Up to the point in time when the hydraulic system made its appearance, 2 years had already passed, during which time merely half of the main sewer could be freed from concrete.

Der KASRO Hydraulikroboter "Goliath" von DN 250-600 mit 5kW FräsmotorThis system was made available to Entech as container solution under the direction of project manager Holger Müller from ProKASRO. Its efficiency in this special case was going to be tested in the USA within the scope of a pilot project. In his own words, Mr Camali had been looking for suitable equipment all over the world and had eventually found what he was looking for at the manufactory in Karlsruhe. Up to the point in time when the hydraulic system made its appearance, 2 years had already passed, during which time merely half of the main sewer could be freed from concrete.

After the Goliath system was put to application, a mere 6 weeks passed before the second half of the sewer was also cleared of concrete.

"Once the Goliath system was put to use, our problem was solved. The concrete could be removed in the space of a few weeks. I was very impressed by the hydraulic milling force and just as fascinated by the durability of the milling head,” Daniel Lefkowitz testifies after successful completion of the construction site.

ProKASRO goes Social Media!

Since July 2017 ProKASRO intensifies their Social Media activities on Facebook, Twitter, Xing, LinkedIn and Youtube. From now on you can see and experience all our news, events, photos, videos and other interesting topics on the ProKASRO company profile and on the mentioned platforms. So, come and visit us frequently.