ProKASRO News 03/2016

Dear customers, partners, and interested persons,

The last third of the year is upon us and we are pleased to present the latest news from ProKASRO.

***Successful construction with a UV liner over 280m long and DN 1500 ***

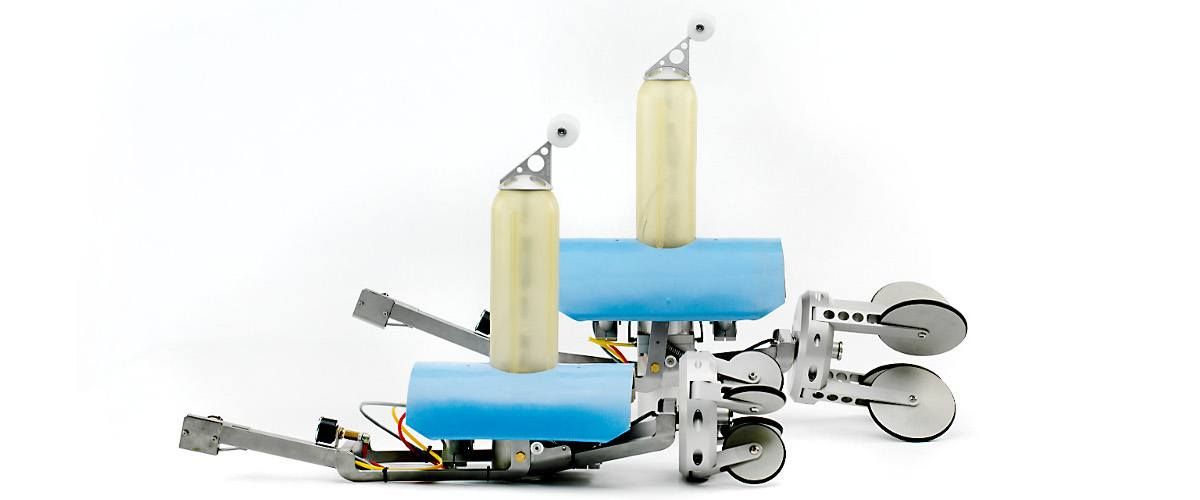

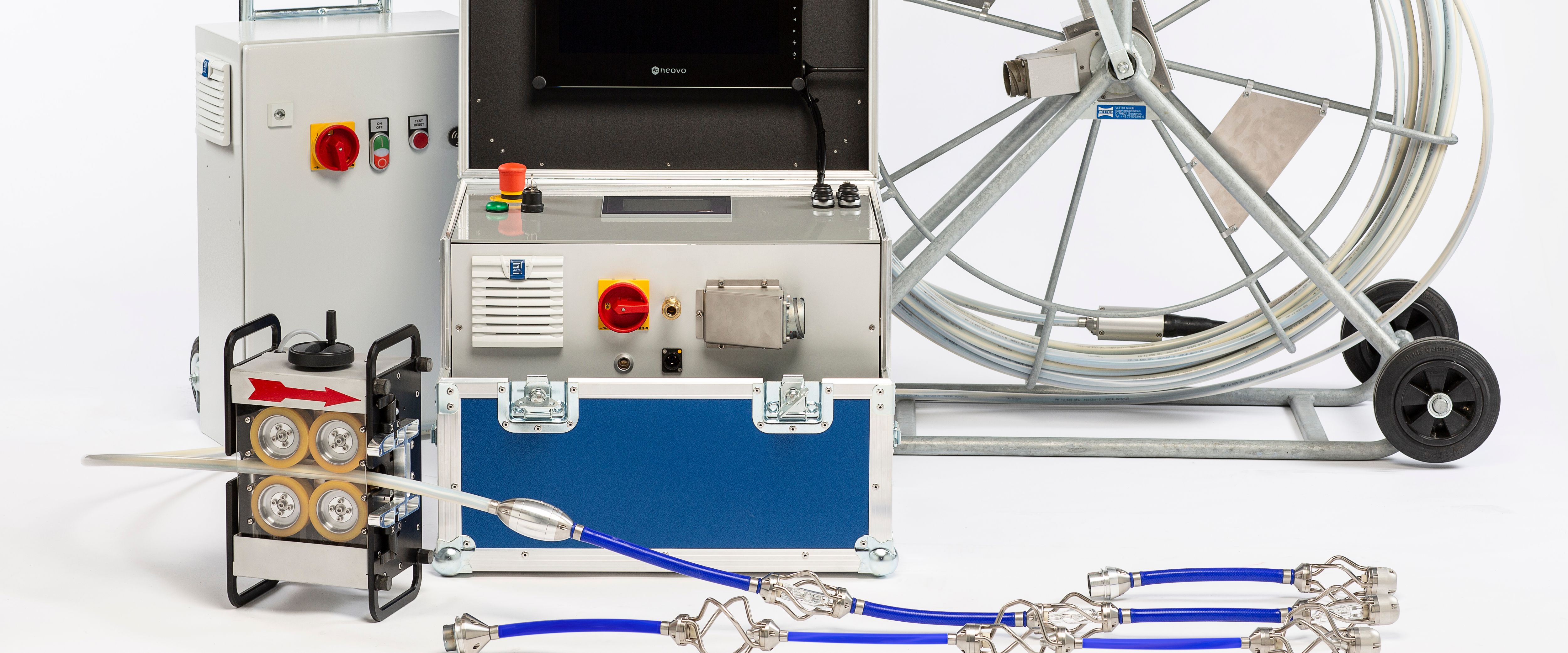

In mid-August, KASRO UV Technology with a dual core 2 x 6 x 1000W, was used on a remarkable construction site in Krakow, Poland that posed several problems for those involved. The project involved curing a liner with the remarkable length of 280 metres, a diameter of DN 1500 and a thickness of 10mm. Additionally, the culvert to be renovated ran under the Vistula (Wilsa) river, making the situation even more difficult. The contracting firm on site was Akwa, who consulted the liner manufacturer Brandenburger and the UV provider ProKASRO. Akwa had already been working on cleaning and preparing the pipe 8-10 weeks before the curing stage. In order to open the pipe, a 6m deep hole had to be dug on the edge of the river and then a 1m diameter hole was drilled in the wall of the culvert. Once the opening was free, the liner could be drawn in and the KASRO UV core inserted. The jumbo core proved here once again how powerful it can cure liners even under difficult conditions. With a remarkable passage speed of 0,66m/min, the KASRO light source core was drawn through the liner and was able to completely cure it in just under 7 hours. Akwa, Brandenburger and ProKASRO worked together to master this task with ease. This was the first liner of such an incredible length to be cured worldwide, making all of us at ProKASRO particularly proud

***Restoration of drinking water lines with the KASRO Filling Robot***

Since July 2016, the water lines are being reconstructed in Alserberg in Wissen in the district Altenkirchen. The approximately 45 year old pipes must be replaced with steel pipelines. For this construction, the con-tracting firm Hubert Niederländer, chose a double line to ensure the local population a continuous supply of fresh drinking water. In the event that a pipe becomes damaged, the water can flow completely through the second pipe. Another feature, and the point at which ProKASRO came into the picture, was the connection of the individual pipes. Sockets were used to connect the lines instead of the conventional method. The concrete-insulated pipes were welded together, creating welding seams which were not insulated by the concrete. To ensure that the pipes and drinking water remain clean and bacteria-free, the welding seams had to be filled with a protective coating.

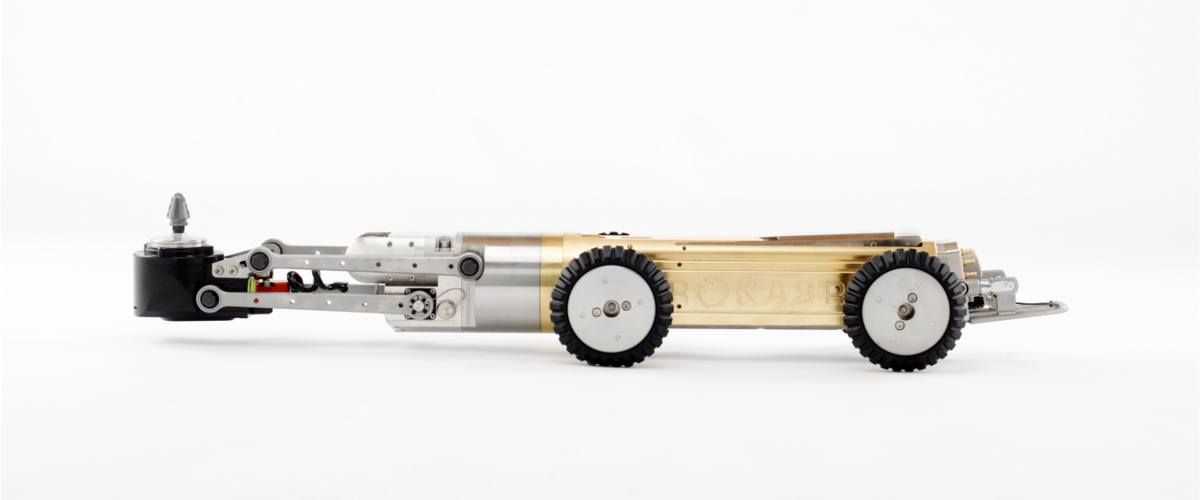

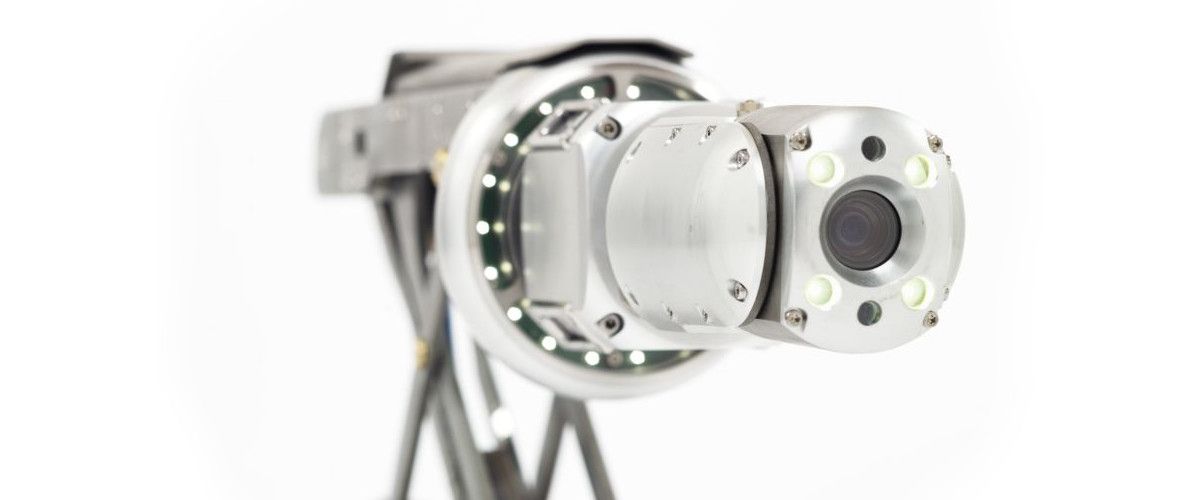

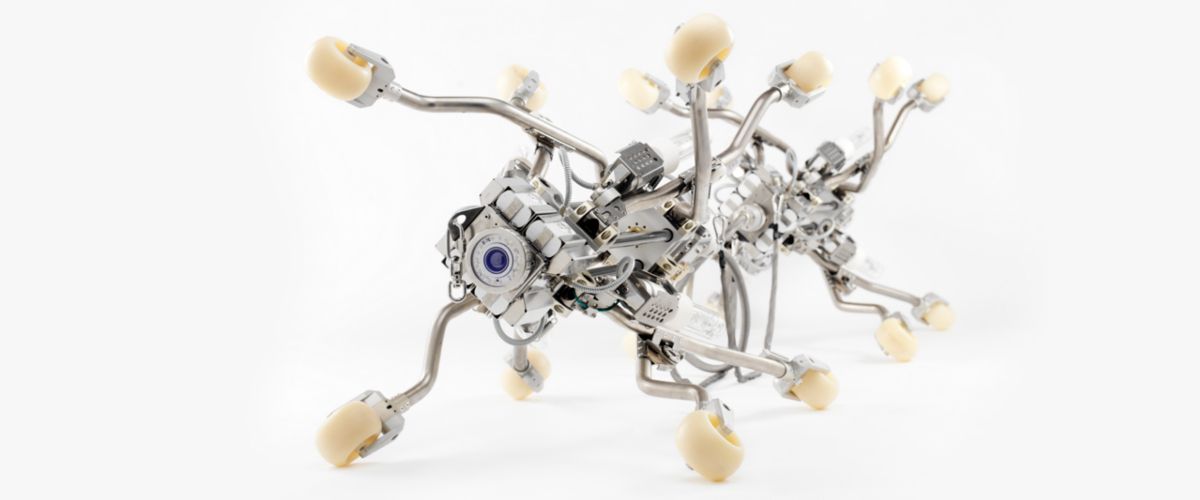

Since July 2016, the water lines are being reconstructed in Alserberg in Wissen in the district Altenkirchen. The approximately 45 year old pipes must be replaced with steel pipelines. For this construction, the con-tracting firm Hubert Niederländer, chose a double line to ensure the local population a continuous supply of fresh drinking water. In the event that a pipe becomes damaged, the water can flow completely through the second pipe. Another feature, and the point at which ProKASRO came into the picture, was the connection of the individual pipes. Sockets were used to connect the lines instead of the conventional method. The concrete-insulated pipes were welded together, creating welding seams which were not insulated by the concrete. To ensure that the pipes and drinking water remain clean and bacteria-free, the welding seams had to be filled with a protective coating.  This task was accomplished by the electric KASRO Robot 4.0 with filling attachment. This robot works its way through the lines applying a special drinking water-suitable resin onto the individual welded pipe transitions of the double lines. As the pipes had a diameter of DN 600, a manual operation was impossible. Thanks to a small camera, the operators could follow and control the path of the robot via a live transmission. After several weeks, water samples were taken to test whether the sterile seal made by the KASRO Filling Robot was successful or not. For this test, the newly filled pipes were disinfected and placed under water for a week. This water test was to show whether or not toxic chemicals were released from the resin mixture during this time. This was 100% ruled out and therefore another difficult challenge for ProKASRO can be logged positively in the books. If the technology from ProKASRO had not succeeded, the construction would have literally been a washout. The end result is impressive. We definitely expect further follow-up orders as up until now, no one other than ProKASRO has mastered such a construction.

This task was accomplished by the electric KASRO Robot 4.0 with filling attachment. This robot works its way through the lines applying a special drinking water-suitable resin onto the individual welded pipe transitions of the double lines. As the pipes had a diameter of DN 600, a manual operation was impossible. Thanks to a small camera, the operators could follow and control the path of the robot via a live transmission. After several weeks, water samples were taken to test whether the sterile seal made by the KASRO Filling Robot was successful or not. For this test, the newly filled pipes were disinfected and placed under water for a week. This water test was to show whether or not toxic chemicals were released from the resin mixture during this time. This was 100% ruled out and therefore another difficult challenge for ProKASRO can be logged positively in the books. If the technology from ProKASRO had not succeeded, the construction would have literally been a washout. The end result is impressive. We definitely expect further follow-up orders as up until now, no one other than ProKASRO has mastered such a construction.

From 2001 to 2004 Vincenzo completed his training as a mechatronics engineer at ProKASRO and was subsequently taken on as a service technician. During this time, he carried out commissioning and repairs worldwide. In 2010 he joined the service office staff with continued close customer contact. In October 2013, Vincenzo became part of production management, ultimately taking over vehicle construction management. Through his many years of work, from trainee to department manager, Vincenzo has gained extensive knowledge in all business areas of ProKASRO Mechatronik GmbH. As of September 2016, he will bring his technical expertise to the sales department with particular support in the field. Sales efforts at ProKASRO are very strongly influenced by the individuality of customer solutions. The primary focus of his new duties, therefore, will be the consultation and support of customers when purchasing a new renovation system, and also to offer technical sales support. ProKASRO is convinced that they can expand their market position in the robot and UV area as well as implementing the strategic sales objectives of the company.