Technology that works for You

Trenchless International October 2013

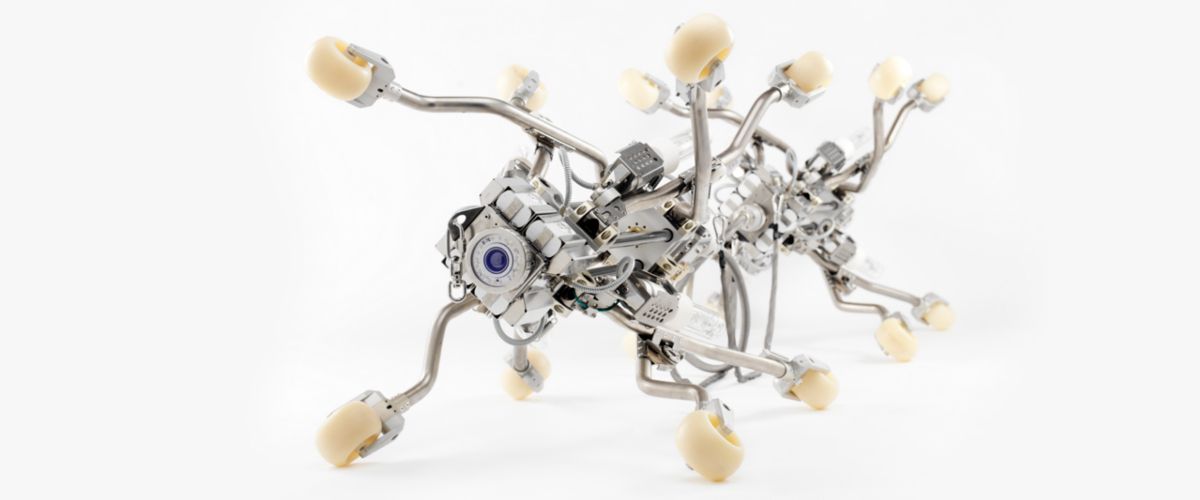

The ProKASRO rehabilitation equipment helps to restore sewers into perfect conditions. This is significantly easier and cheaper than replacing sewer pipes using traditional methods. By using ProKASRO sewer rehabilitation equipment, the entire underground sewer system is safeguarded whilst maintaining ecological, hygienic and technical standards.

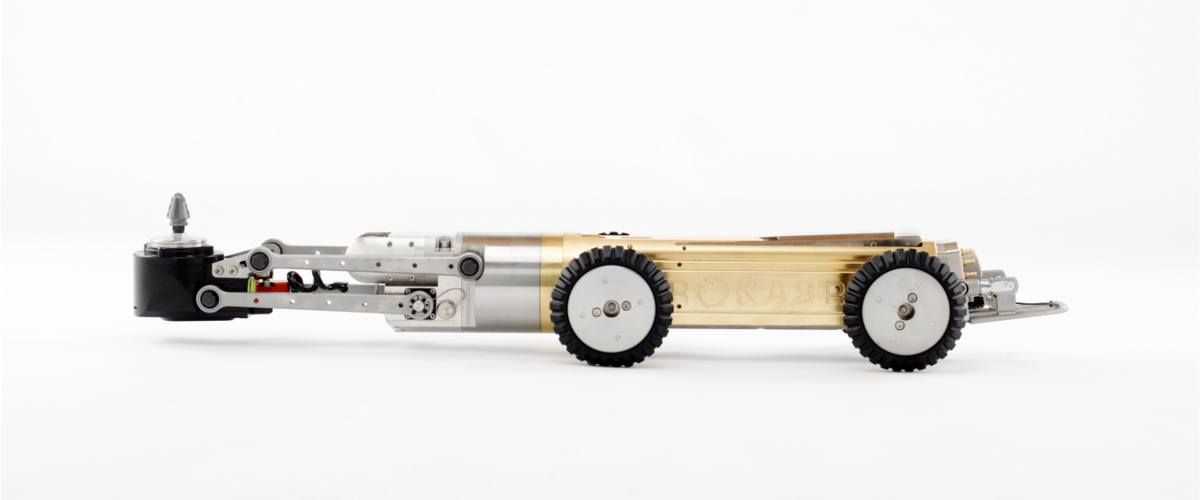

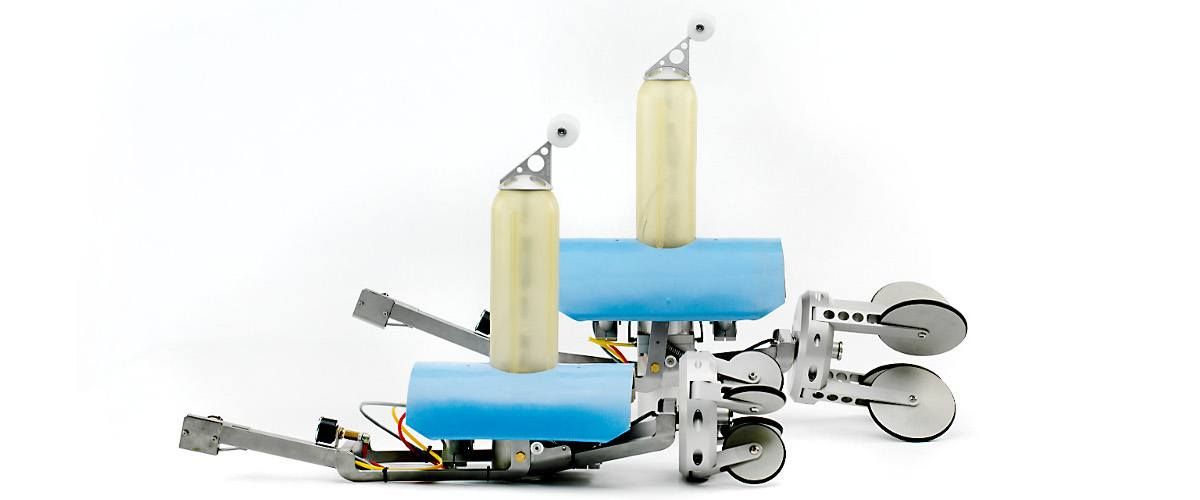

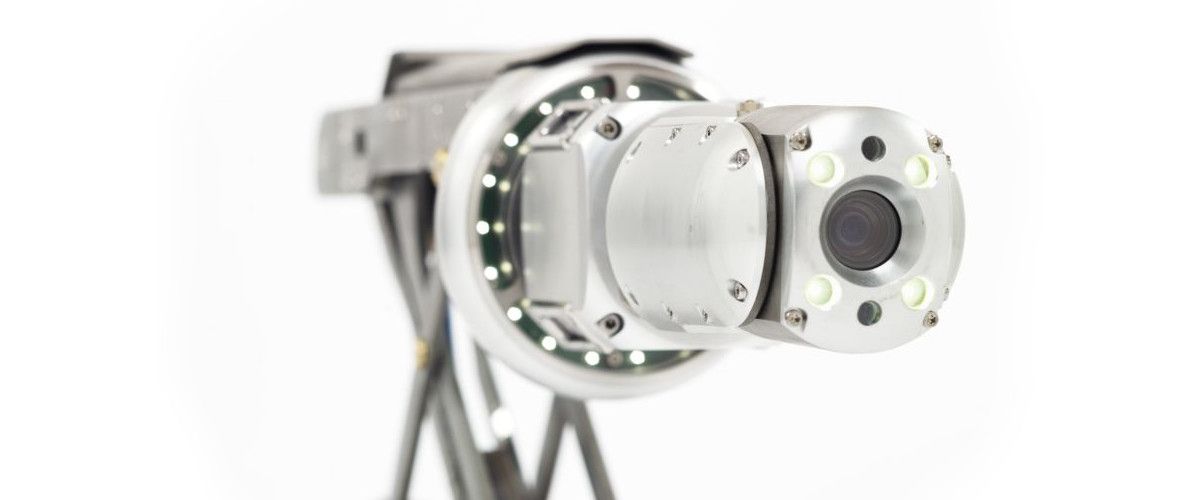

Robots, Systems for Lateral Intake Rehabilitation and UV-Technology; ProKASRO is a full-range manufacturer and supplier for sewer rehabilitation. We enable damage diagnoses and repairs to be carried out without excavation work, traffic obstructions or noise. Working within short rehabilitation timeframes ensures that it is not usually required to block off the sewer during rehabilitation work.

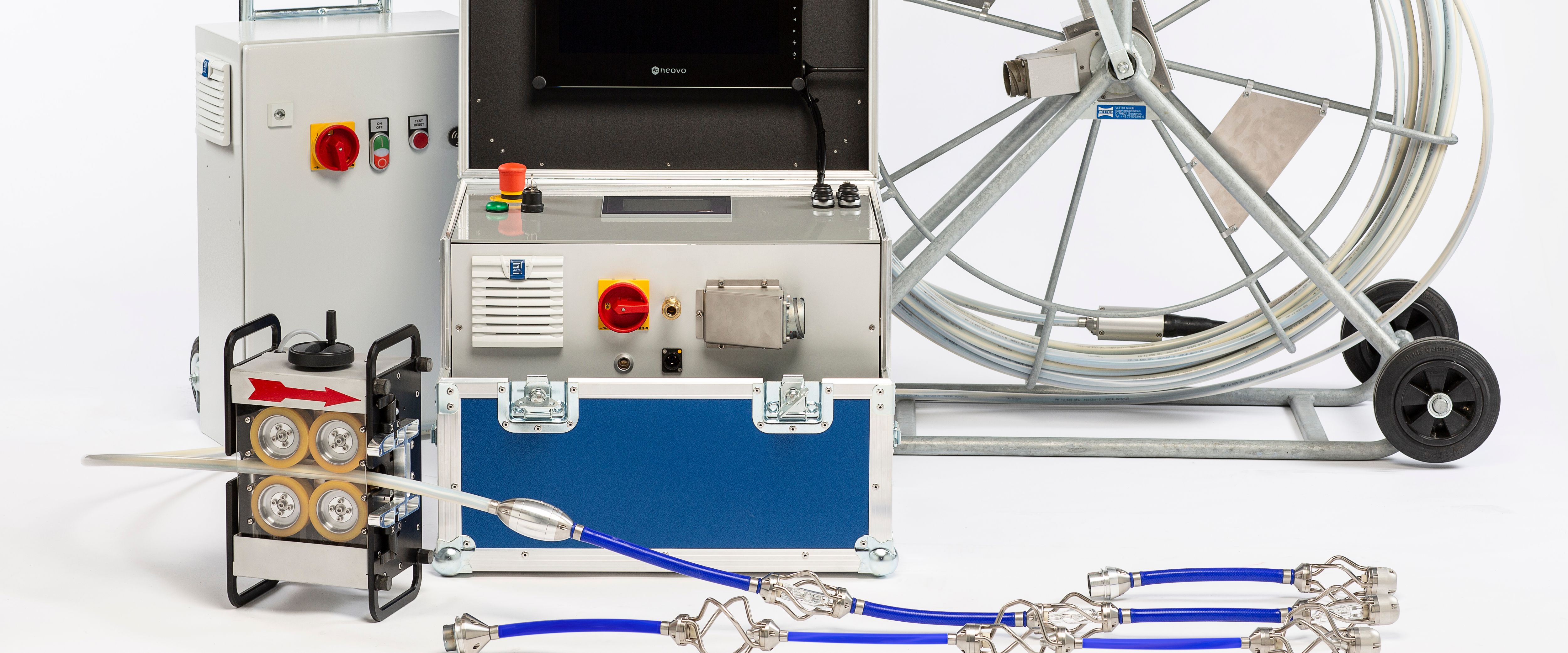

The robot systems and systems for Lateral Intake Rehabilitation can be combined together as required. This means that any rehabilitation system can be operated from the same rehabilitation vehicle or mobile control unit. All rehabilitation work is managed and monitored from a rehabilitation vehicle which is individually designed and constructed to the customers own preferences. On an optional basis transportable mobile control units are also available if preferred or required.

ProKASRO is also the market leader within the field of UV curing Technology from DN150 to DN1500 - whether mobile or within a rehabilitation vehicle.

The ProKASRO rehabilitation systems are designed, developed, constructed and tested in-house. All components are produced and constructed at our manufacturing facility in Germany giving high levels of quality control.

The newest product development is a UV light core which can cure GFRP pipe liners in the largest dimensions up to DN1500. This sets new standards within the industry.

The newest product development is a UV light core which can cure GFRP pipe liners in the largest dimensions up to DN1500. This sets new standards within the industry.

The new KASRO UV core was tested with a GFRP pipe liner with a wall thickness of 13mm. The new KASRO UV double core (12x 1000W, optional 18x 1000W) reached a curing speed of 60cm per minute during the test with a liner of DN1500. With existing UV cores, only 10-20cm could be achieved working in such large diameters.

The benefits are obvious! Liner curing is faster and better due to higher UV lamp performance. With the new Kasro UV double core, the UV lamps move nearer to the liner face during the UV core expansion process which optimizes the curing process and ensures a more consistent cure. Liner production using peroxides is now not necessary so the liners are more stable when stored which minimizes the risk of damages.

Result: the new KASRO UV light double core was tested successfully at DN1500 and is now being used on live work sites. The next tests will show how the KASRO UV system works using the full capacity of three KASRO UV cores in a row. Therefore, a performance of 18x 1000W can now be achieved giving even faster, more consistent liner curing in the largest diameters.

Read more about the existing range of ProKASRO products and all of our new developments on the new homepage www.prokasro.de