E-robots gain popularity in Europe

Underground Utilities 2015

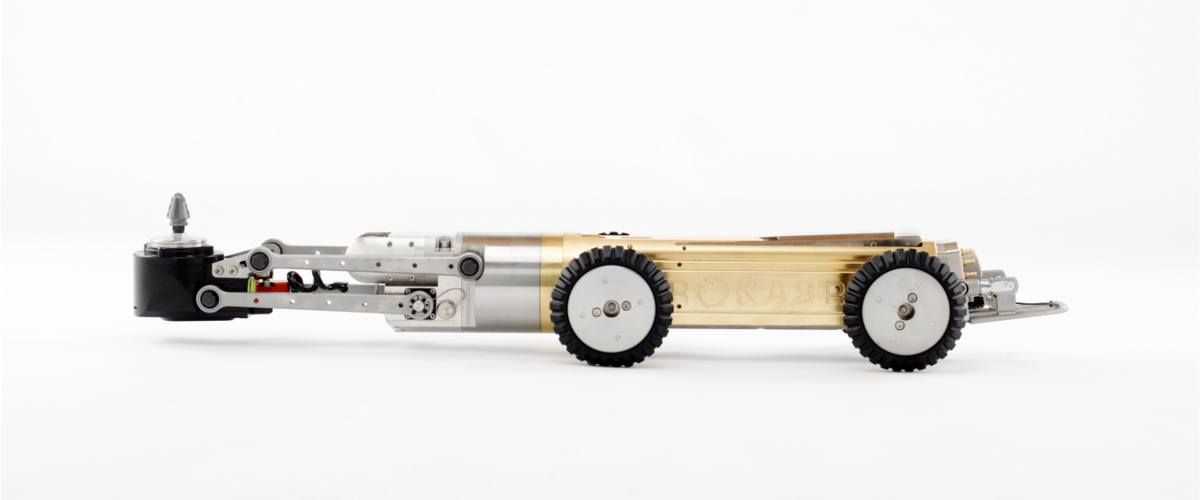

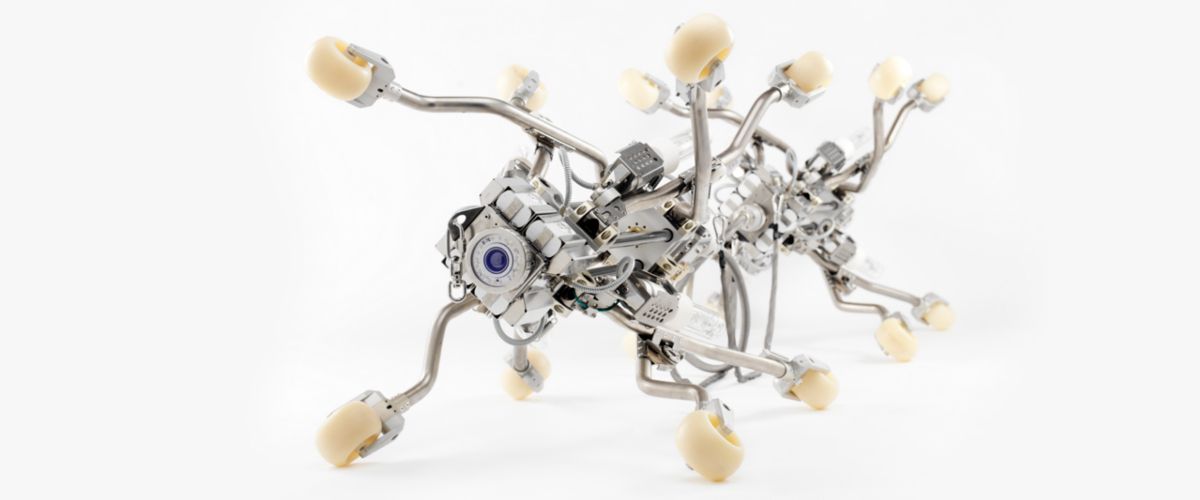

The new KASRO electric milling robot is growing in popularity after a busy year in 2014 which saw it demonstrated in ties all over the world. Since the international exhibition for waste water management IFAT in May 2014 demand increased substantially and to date 70 E-robots have been sold worldwide.

ProKASRO introduced the electric driven milling robot system in 2012 dedicated by demand in the US which it serves through distributor in America Aries Industries Inc. Ten of the new systems have been sold in the US alone.

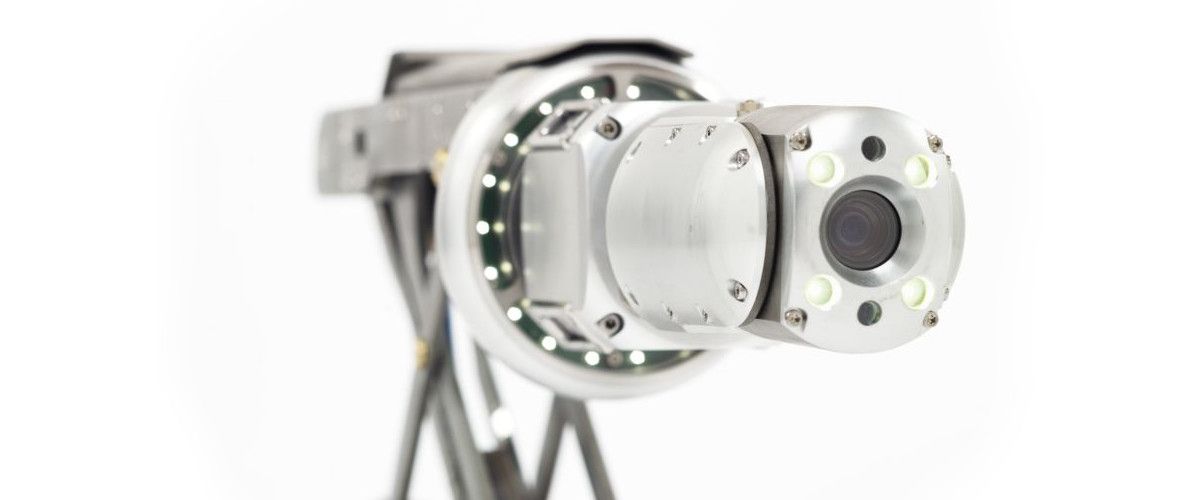

The main benefits of the electric robot are multiple. The motor of up to 3000W enable the highest efficiency during milling works and reduce the rehabilitation time on-site. At the same time the power supply is guaranteed via battery packs with inverter for up to 14 hours continuous use meaning a separate electric generator is not necessary. The electric milling robot also creates a comfortable working atmosphere. The noise level is minimal which is ideal for the neighborhood of the construction site. Milling works can be operated anytime without disturbing the general public.

Finally the aspect of environmental sustainability is important as the electric drive keeps the fuel consumption, CO2-emissions and pollution to a minimum.

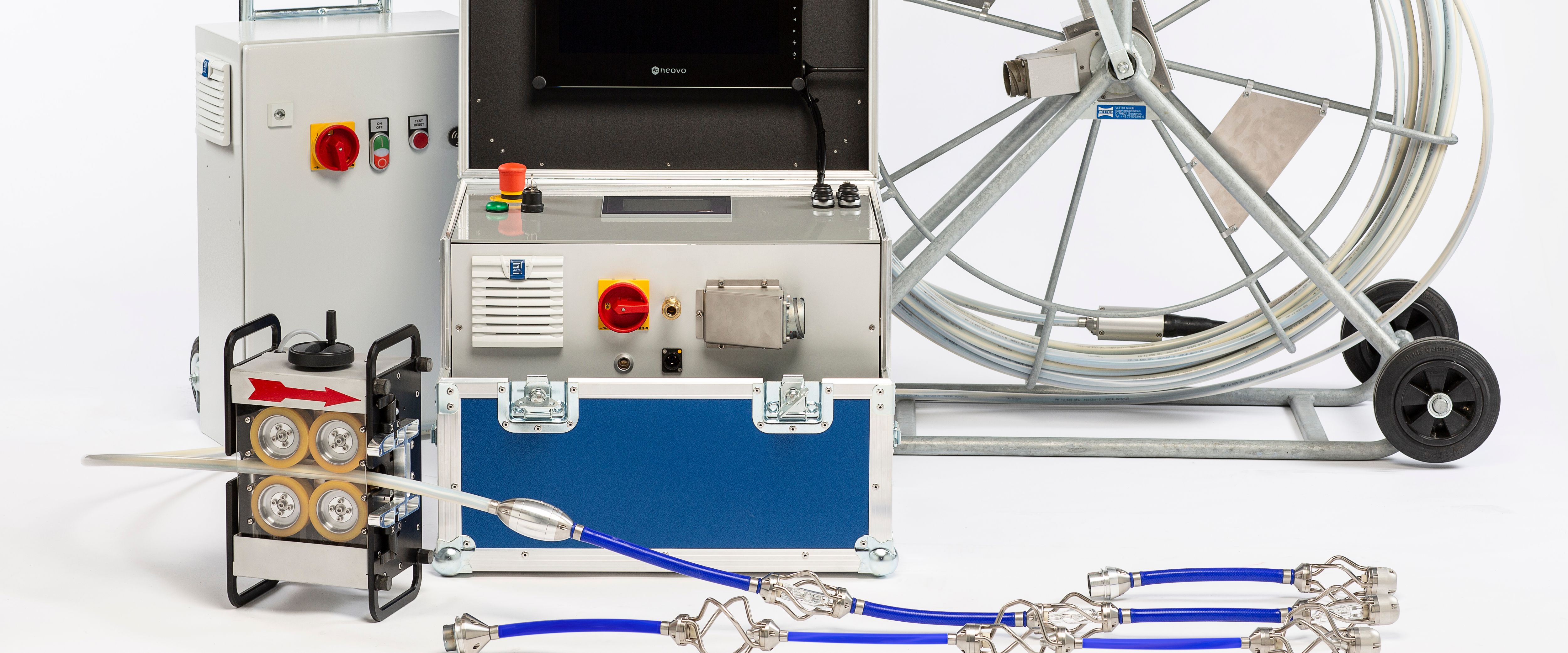

Another advantage outlined by ProKASRO is the space saving in regards to the rehabilitation vehicle as it is now possible to place all the equipment of a complete KASRO electric milling robot system within a 3.5t vehicle. So the tuck or van can be driven by a normal driver´s license negating the need for a driver´s license for heavy good vehicles. Even tight streets can be negotiated with the 3.5t vehicle and the rehabilitation procedure can be operated in an efficient manner even in hard-to-reach areas.

Space saving

The first example of the new electric KASRO working robot within a 3.5t vehicle was introduced during the RO-KA-TECH exhibition held in Kassel, Germany in March 2013 which led to a boom in demand for this type of rehabilitation equipment. The company demonstrated that all tests and construction sites were operated to a maximum satisfaction. During liner preparation or opening lateral connections; the works on-site can take place the whole day without the vehicle losing its battery power.

More recently at IFAT in 2014 the version of a rehabilitation vehicle equipped with electric milling robots, was introduced in a live demonstration. The crowd was huge; many national and international exhibition visitors obtained on-site information about the details of the new technology and tested the KASRO E-robots.

The company says the response was consistently positive and points to the need for robotic technology both before and after rehabilitation of a damaged pipe. Extensive milling works are necessary to remove incrustations, wrinkles, sediments or sockets and cracks.

Marketing manager Franziska Wagner says that the exhibition´s visitors were excited about the performance of the milling motor, especially the smaller model which works from DN130, which demonstrated a similar milling experience to the larger DN250 robot. At the same time the testers could (not) hear, how silently the robots work,” she says.

Spanish tour

Also in 2014 ProKASRO’s Spanish distribution partner TECSAN S.L. undertook a tour of the country’s biggest cities to present the electric version of a rehabilitation milling vehicle to different customers many of whom are already familiar with the pneumatic version. The tour lasted for two weeks. They travelled from Barcelona, via Valencia to Málaga before visiting Sevilla, and heading back to the North to Álava via Madrid. Through the demo tour they were able to get an impression of the functionality of the E-robot and its powerful but silent E-motor. Even ingrained users of the hydraulic milling system were positively surprised by its productivity. The technology of the electric robots does not even need a compressor or generator. The energy supply takes place only via battery packs, which last up to 14 hours. This leads to a minimal fuel and CO2 consumption.

The KASRO E-robot is taking off not only in Spain but also in the rest of Europe including Italy, Switzerland, France, Belgium, Great Britain, even in the northern countries such as Norway and Sweden. Meanwhile also the rest of the world shows enormous interest. Electric robot systems have already been sold to Japan, Australia, and Argentina and to the US. The ProKASRO distribution partner in the US ARIES Industries Inc has already sold more than 10 systems.

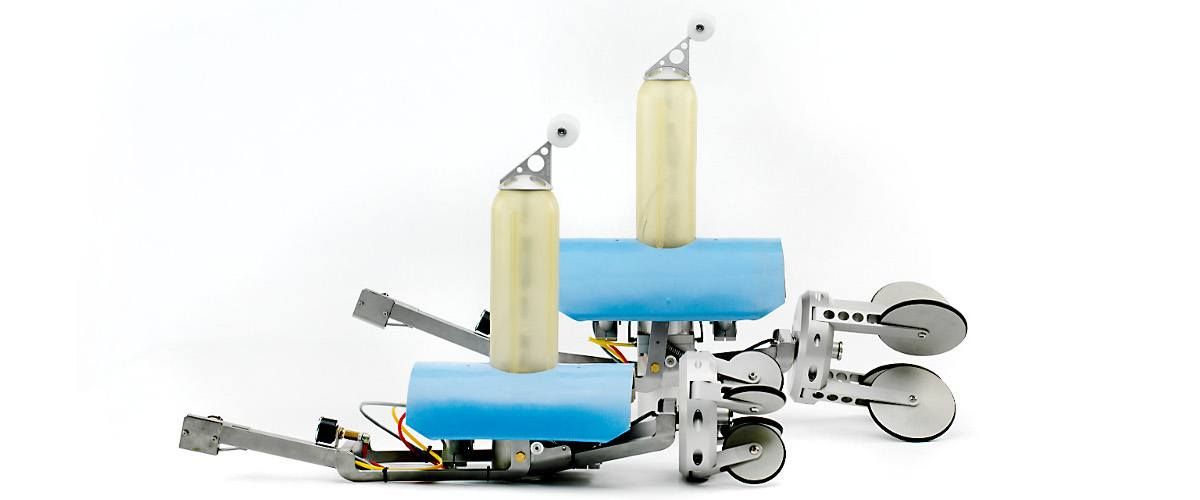

Conversion kits

For customers who work with an old pneumatic rehabilitation system the company offers to convert it to a KASRO electric robot system. In detail this means that the pneumatic driven KASRO milling motor will be substituted with an electric driven KASRO milling motor. “The control unit will get a software update for the electric robot. Within the cable drum an electro cable will be passed through the air hose and the rotary feed will be upgraded. Finally you have the option to remove the compressor and to replace the generator with the long life battery pack,” explains Wagner.