Elements no match for KASRO UV Equipment

Elements no match for KASRO UV Equipment

Battling the harsh elements on an already tricky project requires top of the line equipment to say the least. When such a situation recently arose in Australia, ProKASRO proved itself as a viable solution, yet again delivering high quality rehabilitation equipment when it was most needed.

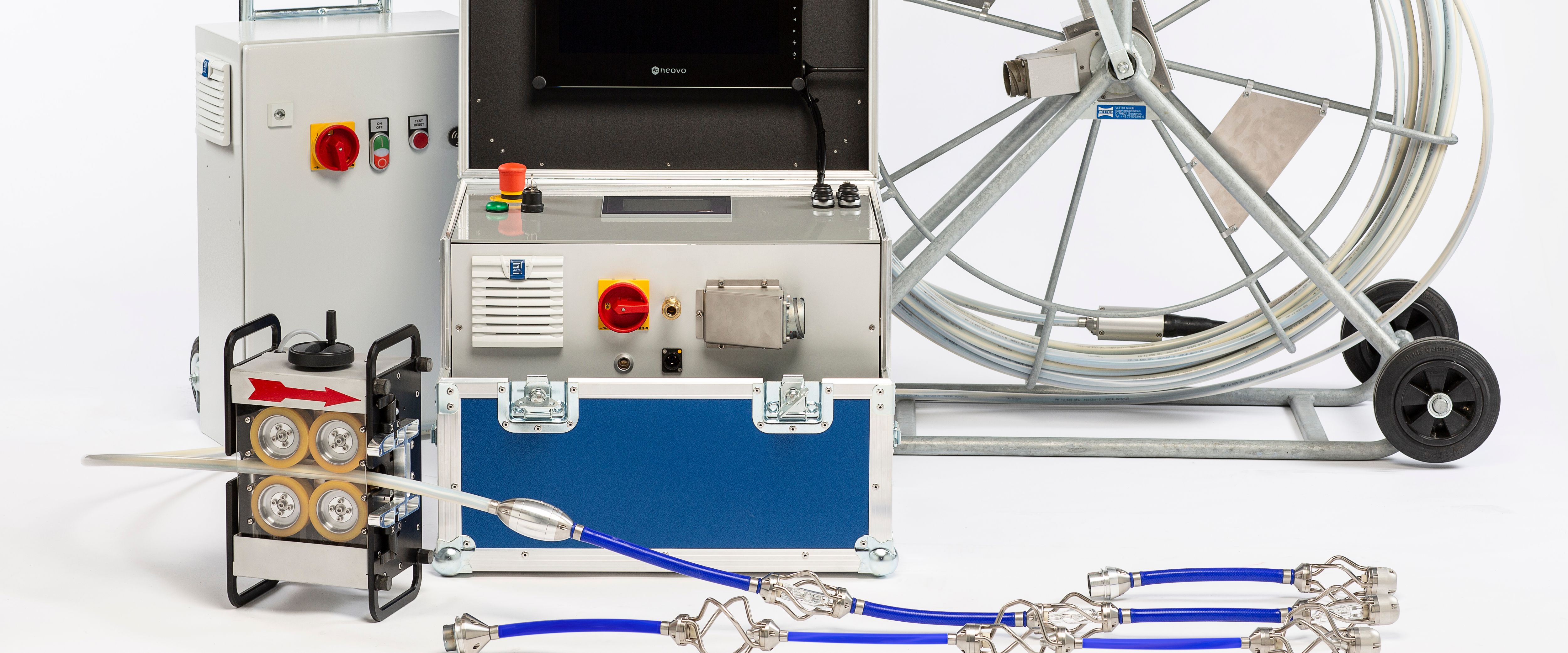

The Aaro Group recen Aaro’s project in Queensland, conducted in difficult terraintly completed a project for Hutchinson Builders as part of the Yeerongpilly Green Development in Queensland, Australia. Aaro was looking for alternative options for the structural refurbishment of an existing 100 m long section of 1,500 mm diameter stormwater culvert that had been deemed unable to be excavated and was subsequently replaced due to numerous site constraints. After assessing the situation, Aaro suggested the most viable solution would be the installation of glass reinforced plastic cured-in-place pipe (CIPP) with KASRO UV curing equipment. In this case, the UV double core 8 by 1,000 W light sounds, controlled by the KASRO UV CCU, was the perfect choice for the DN 1500 pipes on site. In addition, the newly developed 1,000

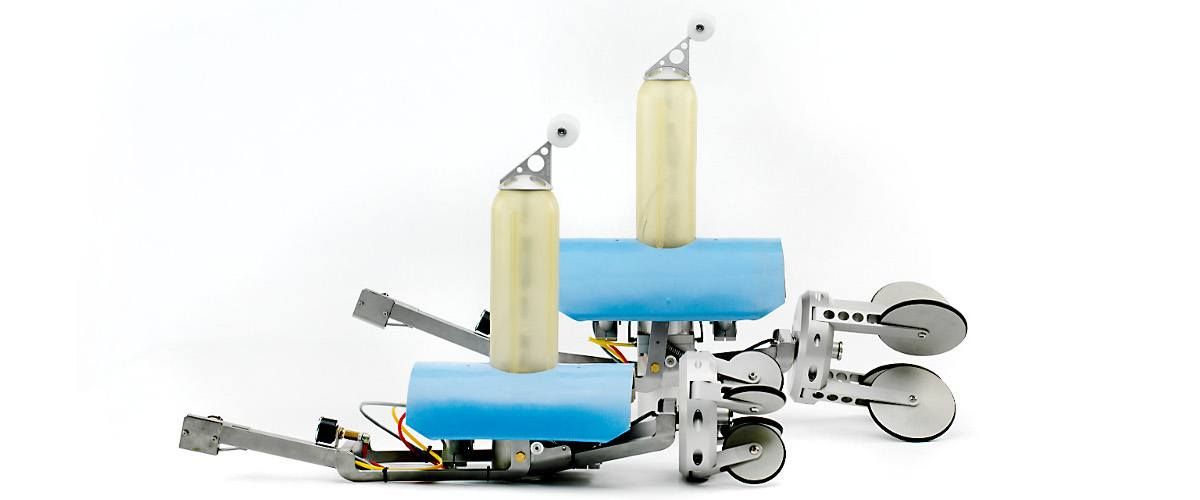

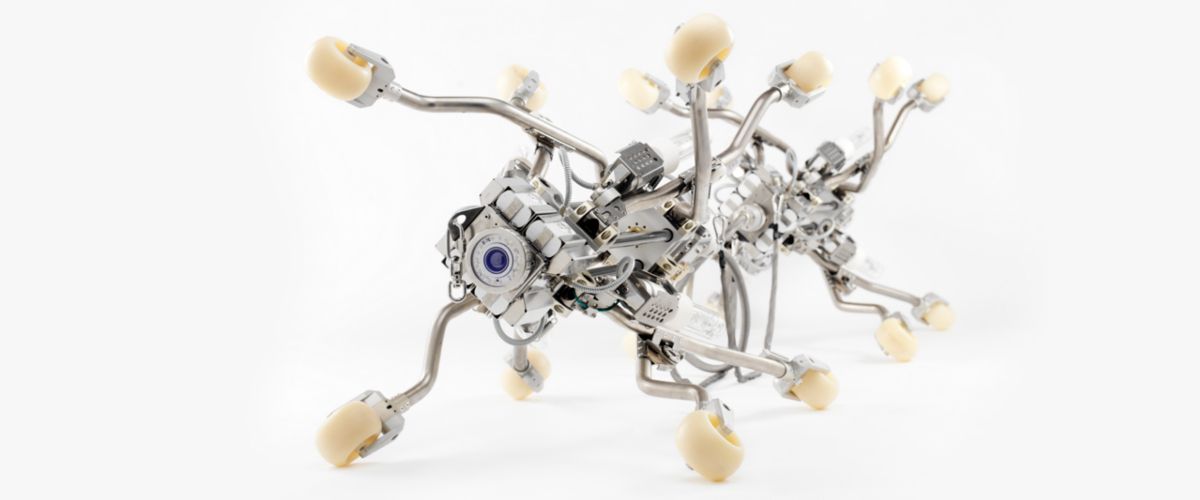

Aaro’s project in Queensland, conducted in difficult terraintly completed a project for Hutchinson Builders as part of the Yeerongpilly Green Development in Queensland, Australia. Aaro was looking for alternative options for the structural refurbishment of an existing 100 m long section of 1,500 mm diameter stormwater culvert that had been deemed unable to be excavated and was subsequently replaced due to numerous site constraints. After assessing the situation, Aaro suggested the most viable solution would be the installation of glass reinforced plastic cured-in-place pipe (CIPP) with KASRO UV curing equipment. In this case, the UV double core 8 by 1,000 W light sounds, controlled by the KASRO UV CCU, was the perfect choice for the DN 1500 pipes on site. In addition, the newly developed 1,000  ProKASRO’s light chain with the newly developed 1000 W bulbsW bulbs contain a special reflector giving approximately 30 per cent higher energy output compared to standard 1,000 W bulbs, guaranteeing a higher quality screening of the hose liner and a larger light cone. While the use of this equipment made it much easier than other options, there were still a wide variety of challenges to be faced on site. To begin with, the headwall outlet ran into heavy marshland on the Brisbane River resulting in the need to build a coffer dam to give the site crew access to that end of the liner while dealing with the tides in the area. To minimize the impact on the marshland bog mats were used on site, while a 100t crane was used for loading and to ensure no damage was done to local trees. Adding to the difficulty, Cyclone Oma formed during the planned window for the works, leading workers to consistently monitor its path through the setup process in order to ensure a safe and true liner cure. Despite the difficult circumstances, the project was completed to a high standard by Aaro Group to the delight of Hutchinson, with ProKASRO UV equipment playing an integral part in this success.

ProKASRO’s light chain with the newly developed 1000 W bulbsW bulbs contain a special reflector giving approximately 30 per cent higher energy output compared to standard 1,000 W bulbs, guaranteeing a higher quality screening of the hose liner and a larger light cone. While the use of this equipment made it much easier than other options, there were still a wide variety of challenges to be faced on site. To begin with, the headwall outlet ran into heavy marshland on the Brisbane River resulting in the need to build a coffer dam to give the site crew access to that end of the liner while dealing with the tides in the area. To minimize the impact on the marshland bog mats were used on site, while a 100t crane was used for loading and to ensure no damage was done to local trees. Adding to the difficulty, Cyclone Oma formed during the planned window for the works, leading workers to consistently monitor its path through the setup process in order to ensure a safe and true liner cure. Despite the difficult circumstances, the project was completed to a high standard by Aaro Group to the delight of Hutchinson, with ProKASRO UV equipment playing an integral part in this success.

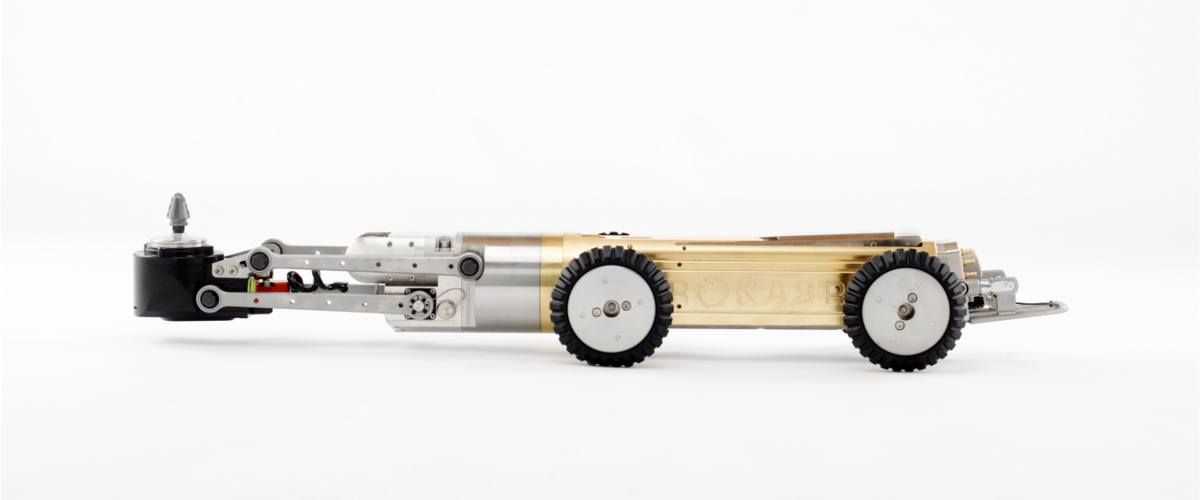

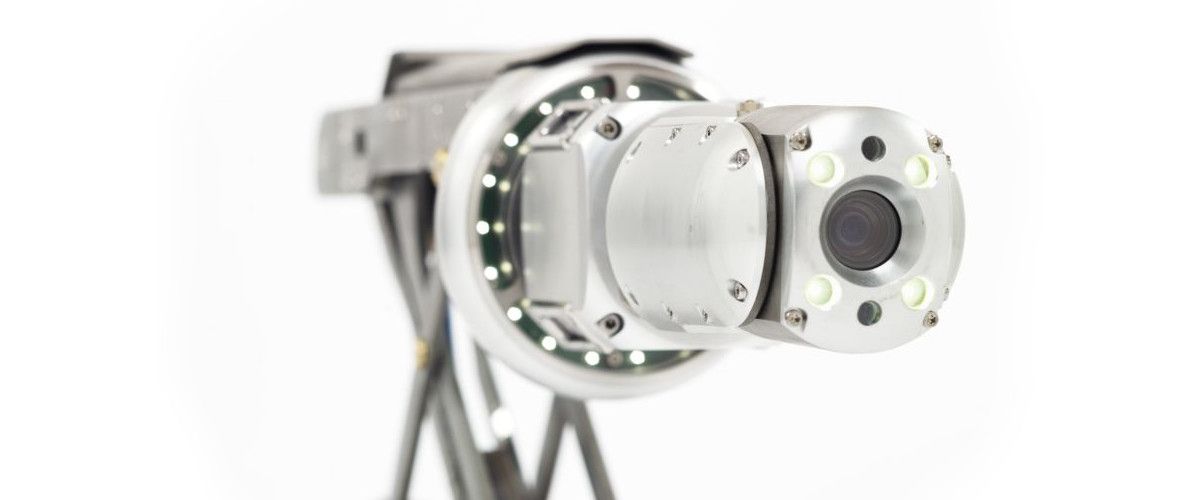

Based in Karlsruhe, Germany, ProKASRO is widely known as a full range manufacturer of sewer rehabilitation equipment, offering trenchless solutions in the robot and UV machinery sector. The dimensions of the KASRO cutting units range from DN 100 to DN 1200 and the UV light cores and chain system cure liners start from DN 100 (house connections) up to DN 1600. At No Dig Florence, ProKASRO will exhibit together with Italian sales partner Geovision, high-pressure cleaning equipment and inspection cameras manufacturer Ibos and fiberglass and carbon liners manufacturer Saertex. ProKASRO is looking forward to welcoming any and all attendees to its stand to see the whole package of solutions, from inspection systems, robot and UV equipment to liner technology.