ProKASRO News 01/2017

Dear customers, partners, and friends of ProKASRO,

From 10 to 12 May, the RO-KA-TECH 2017 will open its doors again and ProKASRO Mechatronik GmbH looks forward to this opportunity to present their current product highlights to all customers and prospective cus-tomers. You can find us at our stand in hall 3:

Stand: Hall 3-4-H3/A06

Our fair highlights:

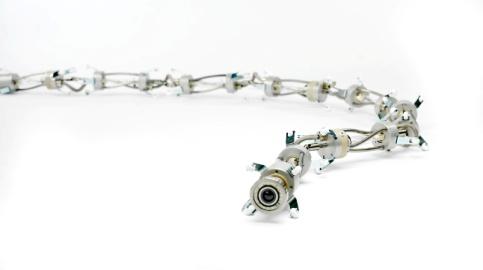

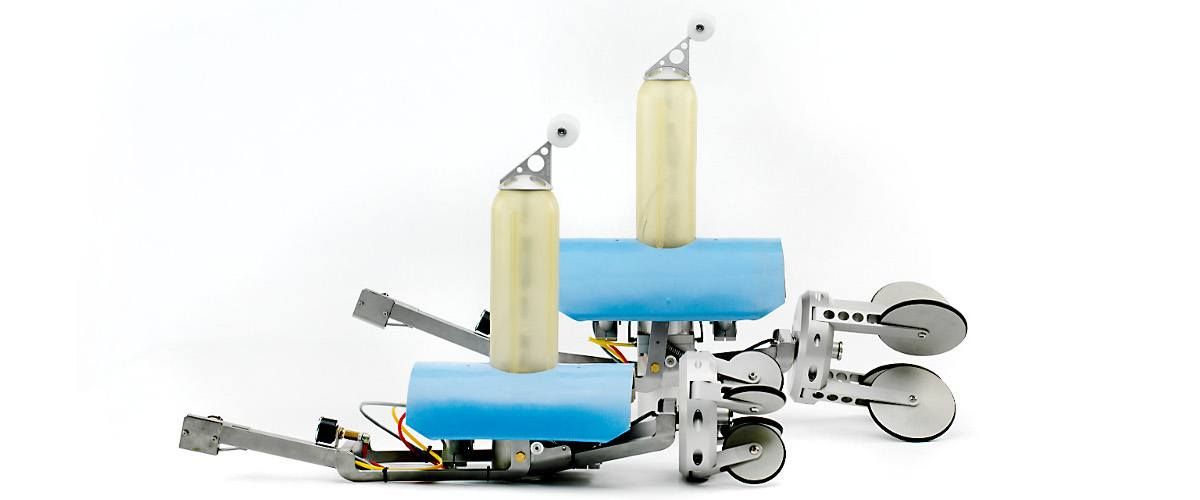

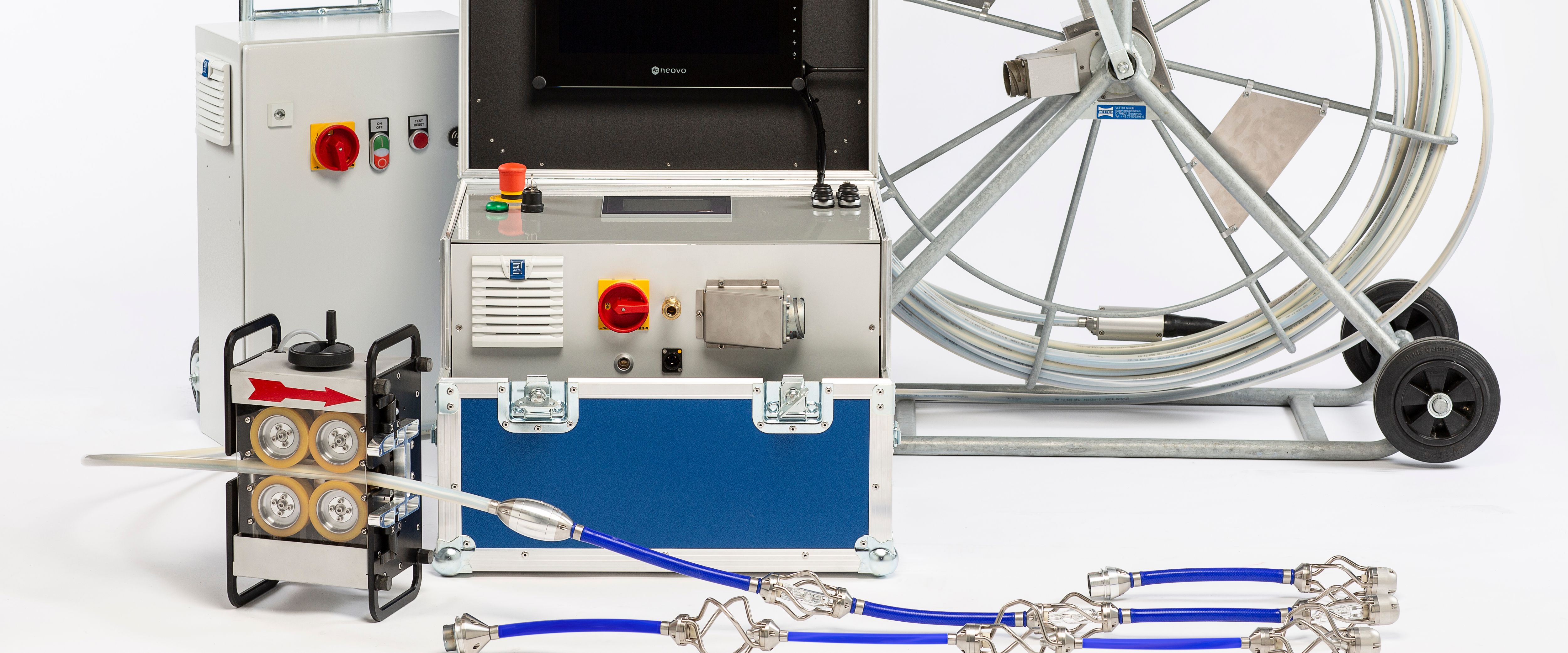

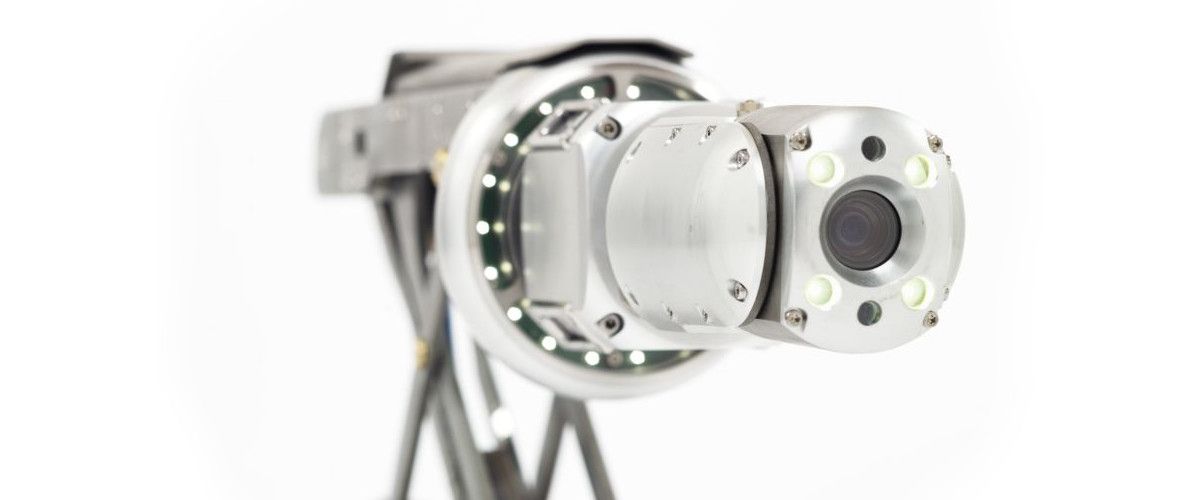

***New bend-capable KASRO UV light source chain for the house connection***

As a special highlight, ProKASRO will be presenting the newly developed KASRO UV light source chain for the house connection range DN 100-200 at the RO-KA-TECH 2017. This innovation offers two different options for the effective curing of fibre glass liners.

One of the alternatives involves feeding the house liner chain in the classical manner into the liner that has been inflated by pressure and to cure the latter by pulling back the UV chain. When the other alternative is used, the chain is directly inverted into the pipe together with the fibre glass liner and is then separated from the liner by means of a patented uncoupling method. The latter is then also cured by pulling back the UV chain.Contrary to normal steam and hot water curing, the liner ar-rives at the construction site already impregnated with resin, as is the case with normal fibre glass UV liners. This makes for faster, cleaner and less complicated working. In addition, considerable savings in water and energy consumption can be achieved. In addition, by applying this more efficient prin-ciple of operation throughout the entire process, the user saves precious time, allowing him to install more liners than usual per work unit. What’s more, the 3 x 200W UV lamps of the house liner chain cure the liner twice as fast as steam or water curing. The light chain is fully bend-capable, as the three ball-shaped chain links are connected with each other in a freely rotating manner. When the push model is used, the individual links are connected with each other by means of a stiff yet flexible PA hose to facilitate the pushing opera-tion. Even the cured end product is improved by the new KASRO house liner chain. As the liners are made from fibre glass and not from needle felt, the cured liner exhibits greater stability and stiffness.

One of the alternatives involves feeding the house liner chain in the classical manner into the liner that has been inflated by pressure and to cure the latter by pulling back the UV chain. When the other alternative is used, the chain is directly inverted into the pipe together with the fibre glass liner and is then separated from the liner by means of a patented uncoupling method. The latter is then also cured by pulling back the UV chain.Contrary to normal steam and hot water curing, the liner ar-rives at the construction site already impregnated with resin, as is the case with normal fibre glass UV liners. This makes for faster, cleaner and less complicated working. In addition, considerable savings in water and energy consumption can be achieved. In addition, by applying this more efficient prin-ciple of operation throughout the entire process, the user saves precious time, allowing him to install more liners than usual per work unit. What’s more, the 3 x 200W UV lamps of the house liner chain cure the liner twice as fast as steam or water curing. The light chain is fully bend-capable, as the three ball-shaped chain links are connected with each other in a freely rotating manner. When the push model is used, the individual links are connected with each other by means of a stiff yet flexible PA hose to facilitate the pushing opera-tion. Even the cured end product is improved by the new KASRO house liner chain. As the liners are made from fibre glass and not from needle felt, the cured liner exhibits greater stability and stiffness.

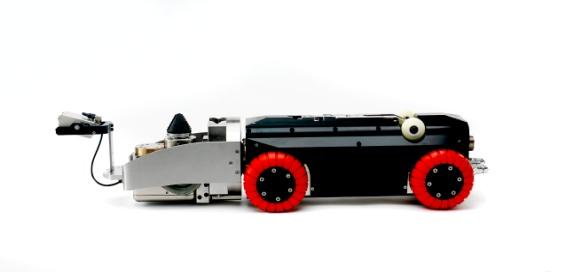

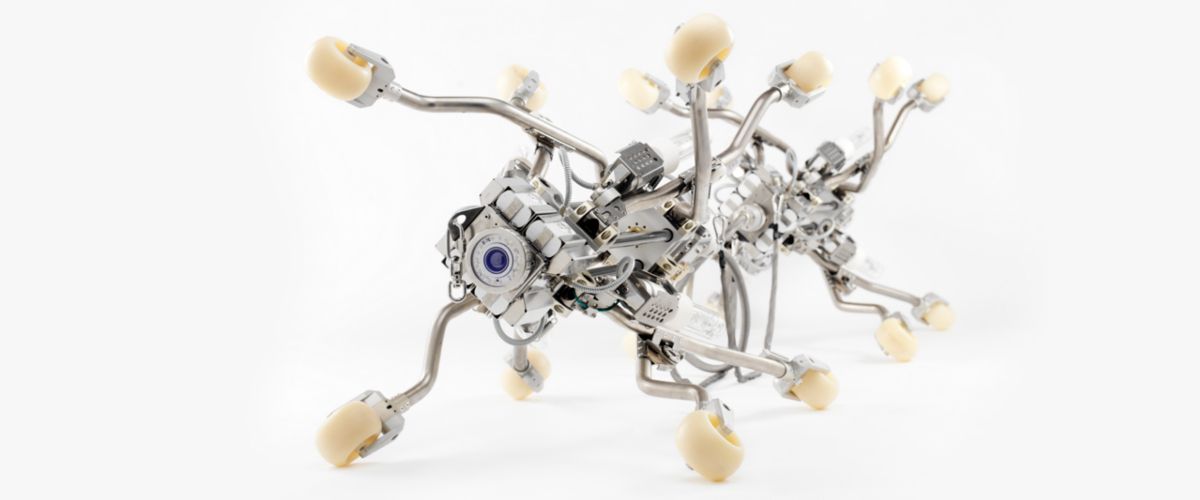

***Dream team: KASRO smART and new KASRO light source chain***

Once the GRP house liner has been cured by means of the KASRO house liner chain, the side inlets have to be milled open again. The KASRO smART house connection robot is optimally equipped for this task and ac-complishes it with ease. Due to its ability to negotiate bends and its powerful electric milling motor, the KASRO smART robot passes even several bends ranging from DN 100 to DN 200 without difficulty. This al-lows it to be deployed from any inspection opening, for example in the cellar, and can thus be used in the narrowest of areas. Additionally, the smART can be pushed in from the main sewer channel. Three 360° cameras allow the operator an optimum view of the side inlets to be milled. Mobility is one of the greatest strengths of the smART and it can thus be effortlessly used even in the narrowest of alleys.

Just a few easy steps are needed to dismantle the KASRO smART into three parts. Mobility and electric milling performance were tested several times during pipe liner preparation and opening of connecting pieces at extremely difficult construction sites. A basic 230V electrical connec-tion suffices to drive the robot. Thus, no additional generator or com-pressor is required. If necessary, special video glasses with Zeiss lenses can be ordered with the robot. This enables the operator to effortlessly monitor milling work even in strong sunlight. With the new KASRO house liner chain and the bend-capable KASRO smART house connection robot, ProKASRO are now able to offer their cus-tomers a comprehensive package that enables them to efficiently carry out the entire house connection rehabilitation.

Just a few easy steps are needed to dismantle the KASRO smART into three parts. Mobility and electric milling performance were tested several times during pipe liner preparation and opening of connecting pieces at extremely difficult construction sites. A basic 230V electrical connec-tion suffices to drive the robot. Thus, no additional generator or com-pressor is required. If necessary, special video glasses with Zeiss lenses can be ordered with the robot. This enables the operator to effortlessly monitor milling work even in strong sunlight. With the new KASRO house liner chain and the bend-capable KASRO smART house connection robot, ProKASRO are now able to offer their cus-tomers a comprehensive package that enables them to efficiently carry out the entire house connection rehabilitation.

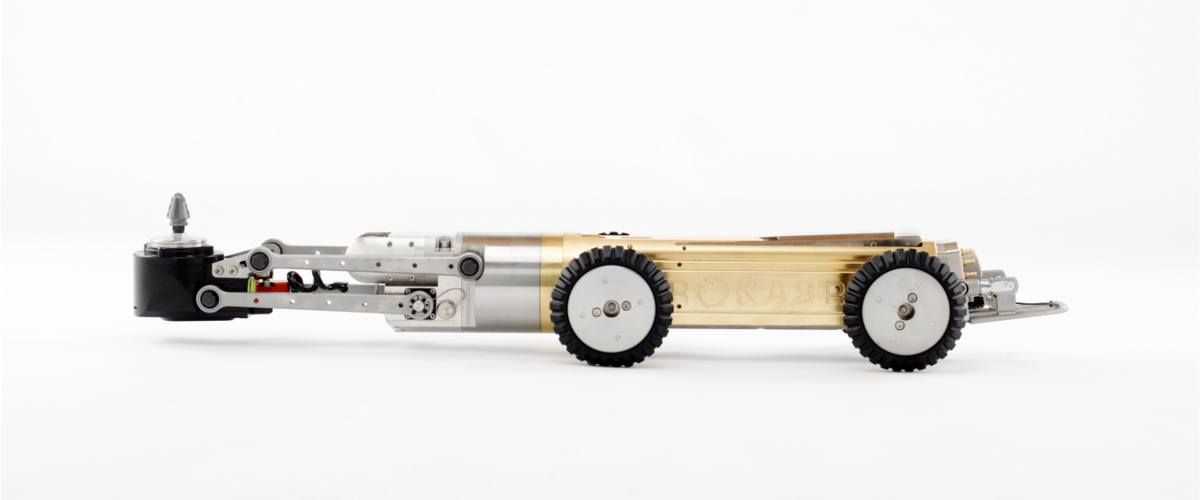

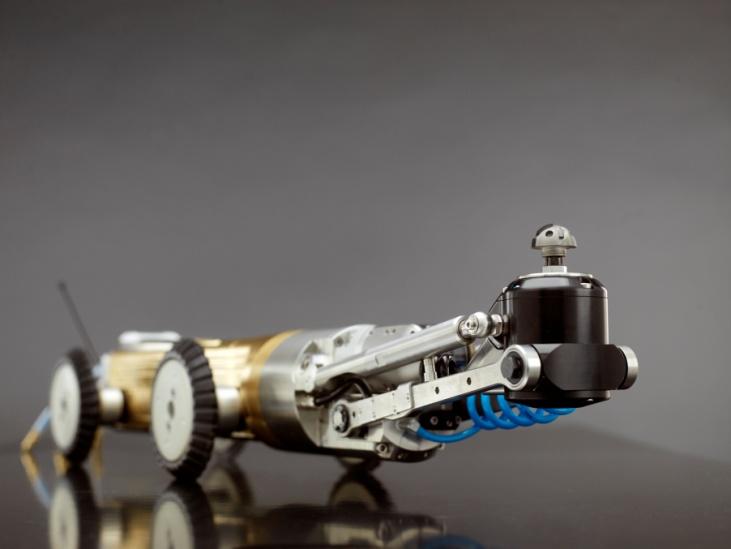

***Enhancement of the well-tried KASRO working robot 1.7***

The electrically driven KASRO working robot 1.7 can now be equipped with a powerful and compact 1200 W slim motor and is therefore well suited for the use in pipes starting at DN 130. Besides, as the robot is equipped with a new 4th axis, the extended range of movement allows it to also mill obstacles head-on. Unproblematic pre-milling of top hat profiles on sloping inlets and branches is guaranteed. This new axis is smaller and sturdier, thus providing a clearer view and easier han-dling inside the pipe. Already in 2012, ProKASRO have extended the product portfolio by electrically driven milling robot systems. A wise investment in the future, which since then has met with a good market response. Today, after almost 5 years, ProKASRO can look back on a total of more than 150 sold electric milling robots 1.7. The KASRO electric motor’s output of up to 2000 W affords highest effi-ciency during milling, thus clearly shortening working times at the construction site. Despite the remarkable milling performance, the generation of noise is kept as low as possible, so that it is virtually possible to work at any time of the day without difficulty. This has already convinced some customers to convert their existing pneumatic system into an electric system.

This and many other highlights from ProKASRO can be experienced at the RO-KA-TECH from 10 to 12 May: